- Home

- SUSTAINABILITY

- Respecting Human Rights and Ensuring Responsible Procurement

- Promoting Sustainable and Responsible Procurement

Promoting Sustainable and Responsible Procurement

Shiseido is committed to sustainable manufacturing across the entire value chain. To ensure that our consumers can choose our products with confidence and peace of mind, we believe that sustainable and responsible procurement is crucial in the supply chain of cosmetic raw materials, which face environmental and social challenges. Among the raw materials, we are particularly focused on transitioning to certified and highly sustainable materials for those that have been assessed as having a significant impact on biodiversity.

We are taking a top-down approach to ensure transparency and clearer raw material traceability. We combine this with a bottom-up approach involving the implementation of the Supplier Assessment Program, which applies the PDCA cycle to identify and resolve environmental and social issues such as human rights, to create a sustainable supply chain built on responsible procurement.

Shiseido Group Procurement Policy

Shiseido Group Supplier Code of Conduct

Shiseido Group Sustainable Raw Materials Procurement Guidelines

Procurement of Raw Materials

Responsible Procurement

Taking responsibility for addressing various sustainability challenges, such as human rights violations, biodiversity, and the efficient use of resources in raw material procurement, contributes to enhancing the long-term resilience of Shiseido's raw material procurement and the entire supply chain. We present a procurement policy, code of conduct, and guidelines to our suppliers to ensure responsible procurement. We are working to clarify the traceability of raw materials that are believed to have a negative impact on human rights and the environment so that issues can be identified and resolved.

In 2020, we published our medium- to long-term targets for the sustainable procurement of palm oil and paper, and we are currently in the process of switching to more sustainable raw materials. For the procurement of palm oil and paper, we support the principles of the No Deforestation, No Peat, No Exploitation (NDPE) and we request that suppliers ensure they are NDPE compliant. The Shiseido Group Sustainable Raw Material Procurement Guidelines clearly state that both environmental and social issues, such as human rights, must be taken into account in ensuring responsible procurement.

Palm Oil

Palm oil is a highly versatile raw material used in a variety of products from food to cosmetics. However, its production has caused significant challenges, including deforestation and human rights violations. Therefore, it is essential for companies to ensure sustainable and responsible procurement of this raw material.

In 2010, as part of our efforts in this area, we joined the Roundtable on Sustainable Palm Oil (RSPO), an international non-profit organization. In 2020, we disclosed our medium- to long-term target of reaching 100% sustainable palm oil in our products by 2026. The relevant teams in our global and regional headquarters have been working to achieve this target ever since. We request all suppliers dealing in palm oil-related raw materials to join RSPO and switch to certified palm oil*1 based on the RSPO’s physical supply chain model. We thus work with suppliers to procure sustainable palm oil-derived raw materials

and survey traceability.

In 2024, we held a session for explaining our procurement policy to suppliers in Japan and requested them to collaborate with us in promoting traceability of palm oil. In 2024, we replaced 80%*2 of palm oil-derived raw materials with certified palm oil based on the RSPO’s physical supply chain model and we purchased RSPO credits equivalent to 100% of the palm oil-derived raw materials we procure. In addition, we continued working toward RSPO Supply Chain Certification at our factories. All of our factories are now RSPO certified.

We have been part of the palm oil working group of the Consumer Goods Forum (CGF)*3, and joined the Japan Sustainable Palm Oil Network (JaSPON) in 2019. They both work to solve issues related to palm oil by strengthening collaboration with other companies. Additionally, we aim to enhance the traceability of all palm-derived materials through activities such as investigating palm oil mills and joining Action for Sustainable Derivatives (ASD)*4. Shiseido is working to enhance the visibility of the upstream supply chain for palm oil and palm kernel oil derivatives by collaborating with companies in the cosmetics, home care, health & personal care, and oleochemical industries through ASD. Continuing with the collection of information on palm oil mills, we aim to enhance traceability by extending it to palm plantations in the future.

Further, through the Shiseido Camellia Fund*5, we support WF Japan’s activities in Indonesia. By training local farmers on environmentally friendly production methods and workplace safety, and by supporting the establishment of producer associations, WWF*6 Japan is helping smallholder farmers acquire RSPO certification and improve their livelihoods. We purchased RSPO credits sold by RSPO-certified small-scale farmers. In doing so, we promoted sustainable procurement in response to environmental and social challenges.

- *1: Raw materials certified by RSPO’s physical supply chain method

- *2: Palm oil equivalent, weight basis

- *3: An international industry group consisting of manufacturers and retailers from the food and consumer goods industries.

- *4: Initiative for sustainable palm oil derivatives

- *5: A fund that uses donations from Shiseido employees and alumni to support the activities of NPOs and NGOs working to tackle social issues.

- *6: World Wildlife Fund for Nature

RSPO, Jonathan Perugia

Check our progress at www.rspo.org

Paper

There are environmental issues associated with the production of raw materials for paper, such as deforestation and loss of biodiversity, as well as human rights issues. We were able to achieve the target of using sustainable paper*1 (use of certified paper and recycled paper) for product packaging and package inserts by 2023. In 2024, we continued to achieve our goals*2, and we also initiated a traceability investigation for the folding cartons procured by our factory and confirmed the origin for 56.8%*3 of them.

Additionally we are switching to sustainable paper for promotional materials and other items. For promotional materials, since 2023, we have been implementing initiatives in accordance with the Shiseido POSM Global Eco Design Guidelines, switching to certified or recycled paper. In addition, we are reducing paper usage by standardizing and unifying some of the cardboard paper for cosmetic sample.

Cosmetics packaging must meet various expectations and standards. It should be sophisticated and beautiful, but also sustainable in its design and strong enough to protect the cosmetics inside. In collaboration with paper manufacturers, we are developing innovative paper packaging solutions that meet and exceed these expectations.

- *1:Use of certified paper and recycled paper from the perspective of forest conservation

- *2:Amount of paper packaging used in 2024 (including estimates): 4,300 t

- *3:Weight basis

Mica

Due to its light-reflecting properties and excellent heat resistance, mica is used in a wide range of industries, including cosmetics. However, it has been pointed out that mica sourced from India, used in cosmetics, may be associated with child labor during its mining.

Shiseido has been a member of the Responsible Mica Initiative (RMI) since its establishment in 2017, in order to effectively handle human rights issues within the supply chain of mica sourced from India.

RMI aims to eliminate child labor and forced labor at mining sites in mica-producing countries to establish mica as a sustainably and responsibly produced raw material. In collaboration with non-governmental organizations, the Indian Government, its member companies, and others, RMI implemented community empowerment programs during the seven years from 2018 to 2024. Specifically, this program helped to improve the incomes and livelihoods of approximately 91,100 people from approximately 16,500 households in 180 mica-dependent villages. RMI initially focused on two states in India. Currently it is implementing initiatives in Madagascar as well.

Sourcing mica produced in India from RMI member companies allows us to confirm that there are no human rights issues. We will continue to strive to procure mica sourced from producers with no social responsibility issues.

Responsible Mica Initiative

Initiatives for Far-reaching Traceability

We use a wide variety of raw materials including materials listed in the Shiseido Group Sustainable Raw Material Procurement Guidelines. We aim to identify and address raw materials-related issues promptly.

●Industry-wide Efforts to Ensure Traceability

Since 2023, Shiseido has joined a consortium of 18 cosmetics industry companies*, TRaceability Alliance for Sustainable CosmEtics (TRASCE). TRASCE's long-term ambition is to extend traceability to the entire value chain of the cosmetic industry. Together with the member companies, we have committed to working collectively to map our supply chains across the entire value chain on a common digital platform, Transparency-One, an ISN Company. Once data is collected through the platform, the objective of the consortium is to analyze risks in order to identify supply chains where action plans are needed.

- *18 members of TRASCE: Albéa, CHANEL, Clarins, Cosfibel powered by GPA Global, Dior, The Estée Lauder Companies, Expanscience, L’Occitane en Provence, L’Oréal Groupe, Merck, Naos, Neyret, Nuxe, Groupe Pochet, Groupe Rocher, Sensient, Shiseido and Sisley. (Alphabetical order)

●Support for Raw Material Producers

Shiseido EMEA is promoting initiatives to support raw material farmers through collaboration with other companies. Geranium bourbon, a type of geranium used as a raw material for fragrances, is produced on Reunion Island in France. Women are responsible for much of the production and harvesting. We are in partnership with a supplier and a local agricultural cooperative to improve their working conditions and ensure a stable supply.

As part of our efforts, we invest in a new harvesting machine to ensure sustainable procurement and improve working conditions for women.

In addition, we have formed a partnership with a supplier to secure a long-term supply of molasses alcohol and address environmental and social issues. Since October 2024, we have been purchasing alcohol made from beets grown by farmers engaged in regenerative agriculture.

Biodiversity in the Value Chain

Shiseido’s business activities rely on nature's rich biodiversity.

Through a TNFD analysis, we have examined the relationship between our business and biodiversity and identified raw material procurement as the area of greatest impact, as our dependence and influence on terrestrial ecosystems is particularly high. The findings of this analysis have been disclosed in the Shiseido Climate/Nature-related Financial Disclosure Report.

To promote biodiversity conservation globally, we implement corporate-led initiatives in each region while also encouraging brand-specific activities that reflect each brand's unique identity.

Shiseido Climate/Nature-related Financial Disclosure Report (PDF)

Corporate Initiatives

As part of the SHISEIDO BLUE PROJECT led by brand SHISEIDO, Shiseido EMEA reinforces its commitment through the M.A.R.E. (Marine Adventure for Research & Education), a long-term endeavor launched by the Centro Velico Caprera, Italy's largest sailing school, in collaboration with the One Ocean Foundation.

M.A.R.E. focuses on marine research and education, mapping biodiversity and monitoring the ecosystem health of the Mediterranean Sea to design protection strategies.

Participants of M.A.R.E. project

In Japan in 2022, we began nature conservation activities on Mt. Ibuki*1, an area where medicinal herbs have been cultivated for centuries. In addition to opening our own medicinal herb garden and cultivating herbs, we are working alongside the Reiho Ibukiyama Association―which works to protect the nature around the mountain—to restore vegetation and preserve the abundant nature in the mountain’s foothills. In 2023, to make full use of unused herbs from Mt. Ibuki, we developed herb bath powder SOYU jointly with Matsuda Chemical Industries. We used this product as a reciprocal gift in crowdfunding for nature conservation activities on Mt. Ibuki. In addition, extracts from Japanese ENMEI herb cultivated in a medicinal herb garden are incorporated into the Future Solution LX series within our brand SHISEIDO.

- *A semi-independent peak among the Ibuki Mountains, which connect Maibara City in Shiga Prefecture and the Ibi/Fuwa districts in Gifu Prefecture. It is 1,377 meters high and is one of the 100 famous mountains of Japan.

Click here for the news release regarding the nature conservation activities on Mt. Ibuki. (In Japanese only)

Brand Initiatives

Shiseido engages in a wide range of biodiversity protection activities through many of its brands and business operations in regions.

Since 2019, brand SHISEIDO has been implementing the "SHISEIDO BLUE PROJECT," a global initiative to protect the oceans under the theme "Respect for the Ocean.” To help create more beautiful oceans, the brand has been working continuously with Shiseido teams in many different countries and regions, local communities, and NGOs on beach clean-ups, dune planting, and other environmental activities. In its sixth year, 2024, on World Oceans Day, June 8th, we conducted beach clean-up activities and conservation efforts for marine life and ecosystems in the Mediterranean across 9 locations in 5 countries.

BAUM was established around the theme of coexistence with trees. The brand promotes the sustainable use of forest resources by incorporating circularity into both its products and the wooden parts of their packaging. As part of these efforts, the brand plants saplings grown at its retail stores in two designated forests in Japan. In addition to its ongoing tree-planting efforts in the BAUM Oak Forest since 2021, BAUM launched a new initiative in 2024 to plant trees in the BAUM Hinoki Forest.

BAUM Hinoki Forest

Supplier Management

Ethical Supply Chain Policies and Standards

At Shiseido, we strive to grow our business as well as stimulate the growth of the societies in which we work. But we want this growth to be sustainable and responsible. In all our activities, we seek ways to prevent human rights problems and preserve the environment.

In recent years, as social and environmental issues have become more serious, companies are strongly urged to not only comply with the laws and regulations of each country, but also respect international treaties and conventions and work toward the realization of a sustainable society and world throughout their supply chains. To this end, Shiseido has established standards and policies for procurement.

With the aim of achieving an ethical supply chain, we adhere to the "Shiseido Group Supplier Code of Conduct," "Shiseido Group Procurement Policy," and "Shiseido Group Sustainable Raw Material Procurement Guidelines." Additionally, our suppliers are monitored regularly through supplier assessment and audits, by which we have been promoting sustainable and responsible procurement. To ensure that our purchasing practices do not conflict with the Supplier Code of Conduct and Procurement Policy, appropriate KPIs are set at the global level. The progress against these KPIs is reported and reviewed at the “Meetings of Chief Procurement Officers” and “Sustainability Committee.” Through these efforts, we confirm that we practice sustainable procurement.

We strive to share and resolve issues with our stakeholders and liaise with wide-ranging experts such as international human rights experts and people working in raw material producing regions to make sure our actions always rely on expert knowledge.

Shiseido Group Procurement Policy

Our procurement policy is to respect all our suppliers as well as ensure sustainable procurement taking society and the environment into account. This is because we aim to provide safe products with high quality which satisfy our customers.

We state a policy to create social value with suppliers in addition to economic one such as cost and quality. We define social value as fair transactions, compliance with laws and regulations, respecting different cultures and set of values, respecting human rights and protection of the environment.

To actively promote more sustainable and responsible procurement together with our suppliers, we revised the policy and announced it in February 2022. In the new Procurement Policy, we formulated requirements for our suppliers regarding the environment and human rights as well as introducing a strict, objective risk identification and correction process through third-party audits, clearly stating that we will evaluate our suppliers from the perspective of sustainability.

Shiseido Group Procurement Policy[ PDF : 524KB ]

Shiseido Group Supplier Code of Conduct

We joined The United Nations Global Compact and took this opportunity to establish the Shiseido Group Supplier Code of Conduct. This code of conduct articulates norms related to human rights, compliance with laws and regulations, labor practices, protection of intellectual properties, protection of confidentiality, protection of the environment and fair transactions. We request all suppliers who have transactions with us to comply with these standards.

To ensure sustainable procurement together with our suppliers, we regularly conduct supplier assessment and the supplier assessment program, which includes corrective actions after the assessment.

In the event that any supplier is identified to have violated the code of conduct, they are requested to implement corrective actions, and we support and educate them.

Shiseido Group Supplier Code of Conduct (Issued in Jun 2019)[ PDF : 876KB ]

Shiseido Group Sustainable Raw Materials Procurement Guidelines

We take actions to resolve issues of raw materials that are determined to have a high probability of serious environmental and human rights issues in the country of origin, such as switching to materials with third party certification of zero involvement and joining international initiatives.

In particular, palm oil-derived raw materials, paper and mica cause deforestation and labor issues which have been frequently revisited. Therefore, we announced targets and measures to resolve the issues and set out a guideline to ensure sustainable procurement.

Shiseido Group Sustainable Raw Materials Procurement Guidelines[ PDF : 186KB ]

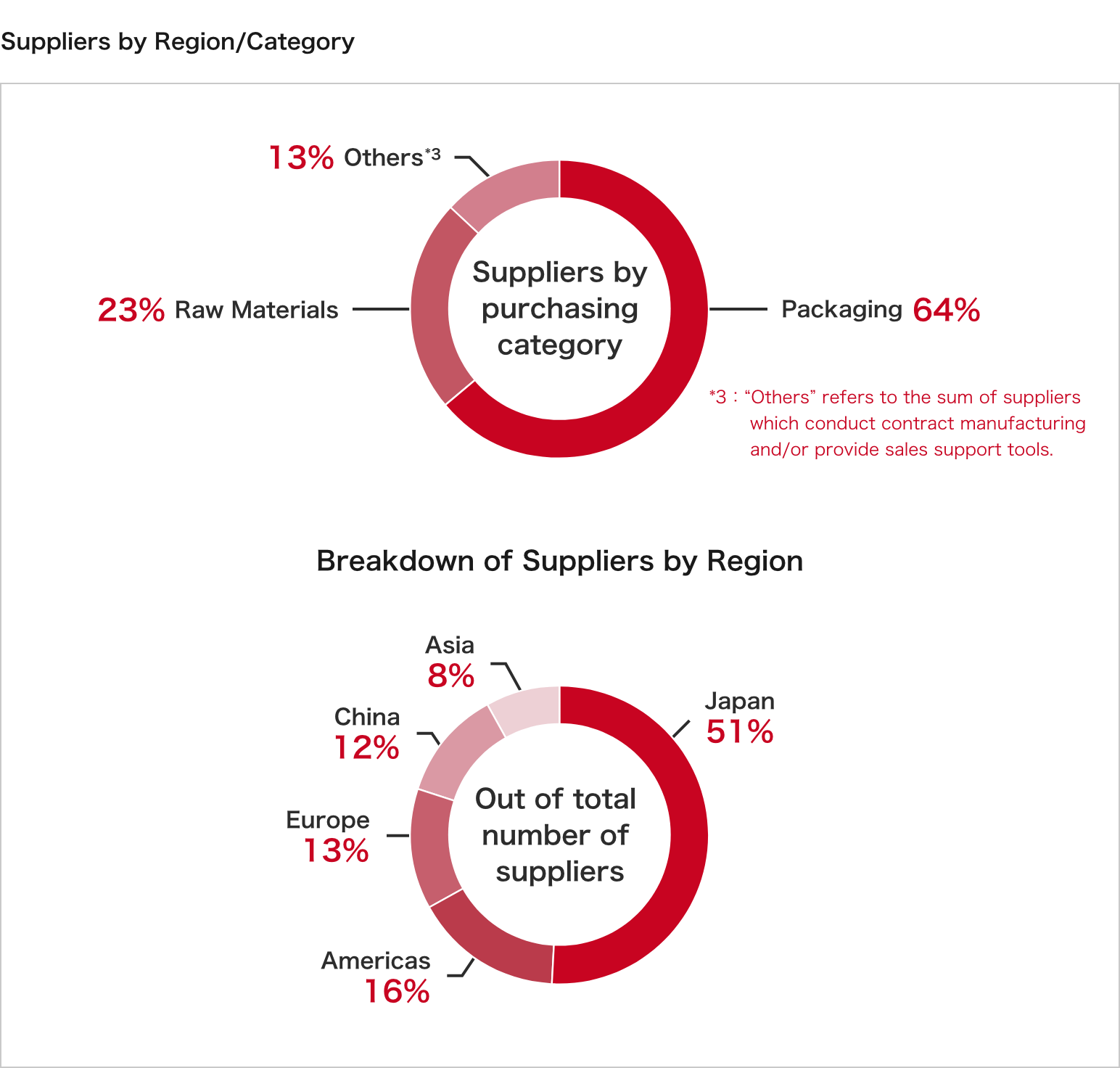

Overview of Shiseido Products and Suppliers

Purchasing Commodities

Items to be purchased include direct materials such as raw materials and packaging for our products, sales support tools, OEM products and contract manufacturing goods.

Shiseido does business with 860 suppliers* from various countries and regions around the world based on the Shiseido Group Procurement Policy. Under the policy we build good partnerships, conduct fair purchasing transactions, make sure that contracts are fulfilled, promote responsible procurement, and respect diverse values.

-

*Companies belonging to the same corporate group are counted as one supplier.(Tier 1

suppliers only)

Each company is counted only once even if it appears in more than one category.

Strategic Suppliers

Identification of Strategic Suppliers

We identify strategic suppliers once a year by the following process:

| Conclusion of contracts/commencement of transactions |

|---|

|

|

| Identification of strategic suppliers |

|

Suppliers*1 we want to strategically partner with to become most trusted personal beauty wellness company in 2030. Strategic suppliers are selected based on our procurement strategy as well as share of purchase amount, QCDST*2, sustainability performance, and whether they have key technology, innovation capability to support our core competencies.

|

|

|

| Strategic suppliers |

Number of strategic suppliers

| |

Suppliers |

|---|---|

| Tier1 | 23 |

| Non-Tier 1 | 3 |

| Total | 26 |

Flow of Transactions

| 1. Contact between a new supplier and Shiseido | |

|---|---|

| 1. Proposal from a new supplier | 2. Contacts from Shiseido |

|

|

|

| 2. Review of proposals | |

|

|

|

| 3. Assessment of new suppliers | |

|

We assess the following points.

|

|

|

|

|

| 4. Selection Process for commercialization | |

|

If there are any specific product needs for the contents presented or proposed, we will conduct a detailed examination for future commercialization. We also request that suppliers present a detailed estimate based on the product's specifications. The following factors are concurrently reviewed and verified. We also conduct examination using samples for evaluation. |

|

|

|

|

| 5. Final/conclusion of purchase agreement | |

| Conditions for procurement are thoroughly reviewed and adjusted before concluding the purchase agreement. New suppliers are required to consent to and comply with the "Shiseido Group Supplier Code of Conduct" upon conclusion of the purchase contract. | |

|

|

|

| 6. Start of transactions | |

|

|

|

| 7. Performance review | |

| Once a year, we evaluate the performance of suppliers from the perspectives of QCDST*1 and sustainability*2. For details, please see the Supplier Performance Evaluation section. | |

- *1:Quality, Cost, Delivery, Service, Technology

-

*2:The minimum requirement for doing business with a supplier is that it is assessed as "not high-risk" in terms of sustainability. If a supplier is categorized to be "high-risk", it is excluded from the candidates;

however, if issues are corrected within a certain period and requirements are met, its eligibility may be reconsidered.

Please refer to the Supplier Assessment Program section for the definition of "high-risk".

Category Strategy in Procurement

Shiseido builds category strategy based on purchased commodities and conducts sourcing activities accordingly. The category strategy is created by considering requirements based on QCDST* business aspects, and requirements from a sustainability perspective. The strategy is updated based on category performance which is reviewed regularly and the status of compliance with the Shiseido Group Supplier Code of Conduct.

In these ways, we continuously review our purchasing practices and ensure alignment with the Shiseido Group Supplier Code of Conduct while confirming there are no conflicts with sustainability requirements.

- *Quality, Cost, Delivery, Service, Technology

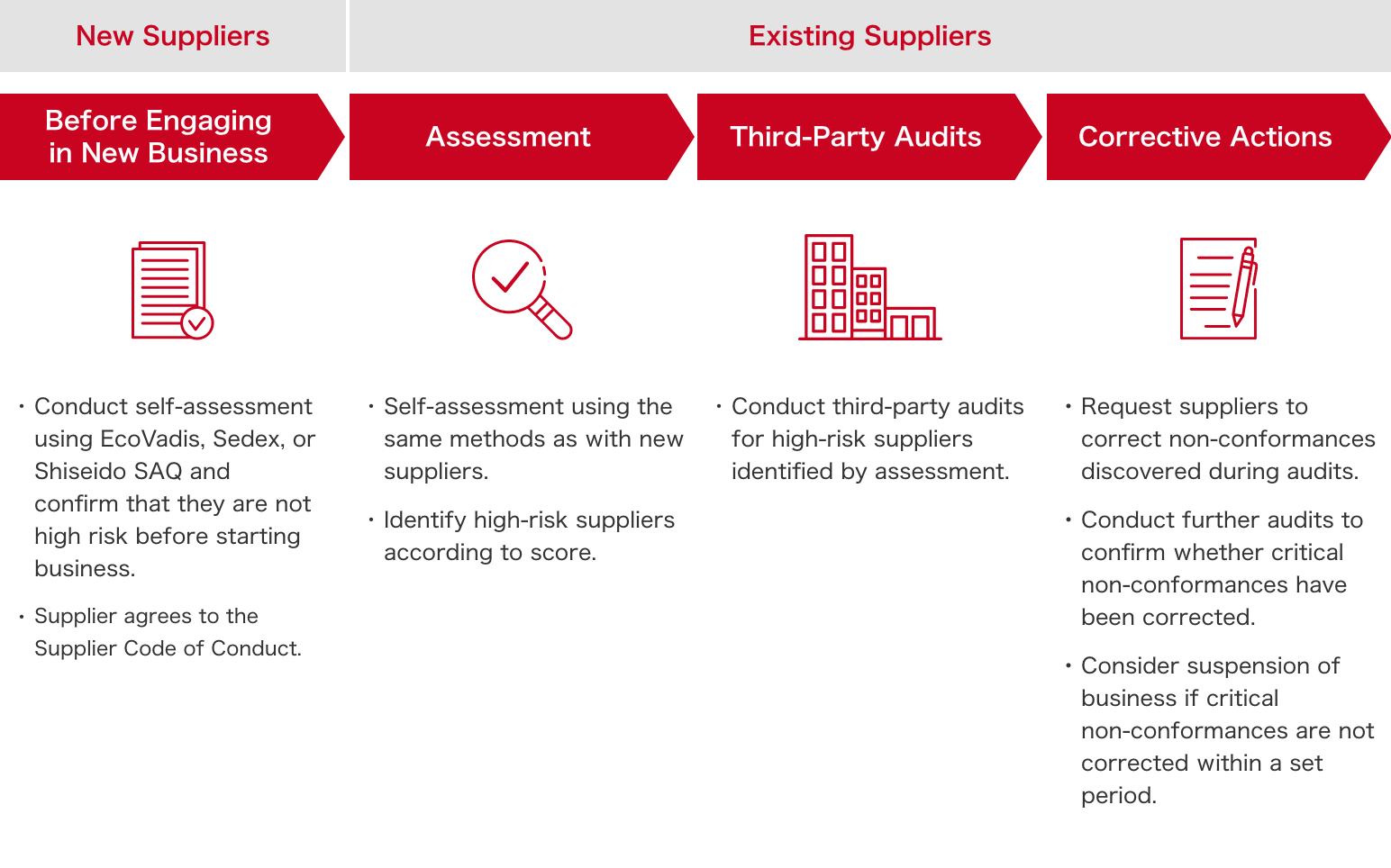

Supplier Assessment Program

Our aim is to create a sustainable supply chain built on responsible procurement and to minimize risk across the entire supply chain. To do so, we are promoting the implementation of the Supplier Assessment Program.

At Shiseido, we implement the program based on the Shiseido Group Procurement Policy which was revised in 2022. We don’t work with suppliers, if they are categorized as high-risk by the assessment and don’t correct non-conformances identified by audits.

We conduct a self-assessment for all suppliers when starting business from the perspective of sustainability (human rights, occupational health and safety, environment, and business ethics) using either EcoVadis, Sedex, or our original Self-Assessment Questionnaire (SAQ) *1.

We start business with new suppliers after conducting supplier assessments, confirming that they are non-high-risk and then agree to be compliant with the Shiseido Group Supplier Code of Conduct.

For existing suppliers, we continuously confirm compliance with the Shiseido Group Supplier Code of Conduct using the above assessments.

We screen significant suppliers*2 based on their degree of risk and importance to our business to prioritize assessments. The screening process considers the risks of suppliers (ESG risks, risks specific to country, industry, commodity), spend, QCDST*3 performance, etc.

Based on self-assessment results, we categorize suppliers into three groups according to the degree of risk: low-risk, medium-risk, and high-risk. If a supplier is categorized as high-risk, we conduct third-party audits.*4

Additionally, we give all suppliers feedback on the results either face-to-face or online, and, if necessary, our employees visit the suppliers’ sites to discuss improvements in their ESG performances.

During third-party audits, employee interviews and verification of required documentation are conducted. High-risk suppliers are then requested to implement corrective action plans, and in the event of critical non-conformance, we conduct further third-party audits to confirm correction status. If issues are not corrected within a set period, we consider suspension of business.

- *1:Please refer to the following table for details about our self-assessment tools.

- *2:Significant suppliers are direct material and POSM suppliers. In 2024, 38 companies were classified as significant suppliers (35 of these are Tier 1 suppliers and Shiseido’s spend on these suppliers accounts for 39% of its global spend). We assessed all of these suppliers and audited one identified high-risk supplier. We confirmed that corrective actions based on the plan were completed.

- *3:Quality, Cost, Delivery, Service, Technology

- *4:WCA audit (a third-party audit company, Intertek’s sustainability audit program), SMETA audit (audit program designed and managed by Sedex), and others.

| Tool | Explanation(main criteria etc.) |

|---|---|

| EcoVadis |

Measure the quality of a company’s ESG management system through its policies, actions and results. The assessment focuses on sustainability criteria that are grouped into four themes: Environment, Labor & Human Rights, Ethics and Sustainable Procurement. The questionnaire is customized according to industry type, location, and company size of the respondent. |

| Sedex |

Evaluate suppliers by the questionnaires based on labor standards, health and safety and business ethics. The number of questions vary depending on industries. The level of risk is calculated based on the answers to the questionnaire. Country and sector specific risks are also considered. |

| Shiseido SAQ(Self-Assessment Questionnaire) | Based on Shiseido Group Supplier Code of Conduct, the SAQ evaluates suppliers from four criteria: human rights and labor, occupational health and safety, the environment, and business ethics. |

Shiseido is gradually expanding the scope of its Supplier Assessment Program from the perspectives of procurement category, country, and tier.

From a category perspective, we assess globally suppliers which provide direct materials, OEM products, contract manufacturing goods, and sales support tools. From a tier viewpoint, we assess not only Tier 1 suppliers, but also upstream suppliers; Tier 2, and beyond.

The policy and the results of the Supplier Assessment Program are reviewed by the Sustainability Committee, and then, proposals and reports are made to the Board of Directors.

Results:

Activities in 2024

Tier 1 Suppliers Assessment

In 2024, we expanded the categories of suppliers that undergo the Supplier Assessment Program and started assessing indirect material*1 suppliers, in addition to the program of direct material and POSM*2 suppliers.

For direct material and POSM suppliers, we conducted corrective actions in 2024 for three high-risk suppliers whose corrections were not completed by the end of 2023. We also conducted the Supplier Assessment Program globally for 35 significant Tier 1 suppliers according to the degree of risk and importance to our business. One supplier was identified as high-risk in the self-assessment. The necessary corrections were made by the suppliers and confirmed through third-party audits.

For indirect materials, in preparation for starting self-assessment in 2025, we conducted risk screening for approximately 20,000 companies globally in 2024. As a result, we identified 156 companies that will be subject to self-assessment*3.

- *1:This refers to services and purchased goods that are not direct materials but are necessary for business activities. This category does not include sales support tools.

- *2:Categories: direct materials, OEM products, contract manufacturing goods, and sales support tools

- *3:Scope of the assessment is based on priorities derived by using IQ Plus, a screening tool from EcoVadis, which screens suppliers based on county, industry sector, spend and others.

Tier 1 Suppliers Assessment Results

| Year | No. of Suppliers Assessed | No. of High-Risk Suppliers Identified | No. of High-Risk Suppliers(at end of FY2024) |

|---|---|---|---|

| 2021 | 279 | 17 | 0 |

| 2022 | 67 | 10 | 0 |

| 2023 | 860 | 12 | 0 |

| 2024 | 35 | 1 | 0 |

Assessment of Upstream Suppliers(Tier 2 supplier and beyond)

We also implement the Supplier Assessment Program for upstream suppliers (Tier 2 supplier and beyond), in addition to Tier 1 suppliers. Due to the large number of upstream suppliers, we made a prioritization and based on this, we defined the target suppliers that would go through the assessment program.

Specifically, important manufacturing suppliers that our strategic suppliers (Tier 1 and Tier 2) identified are in the scope. We then requested our strategic suppliers to confirm the risks of these manufacturing suppliers using EcoVadis or Sedex.

As a result, we completed an assessment of 220 upstream suppliers in 2024 and found that none of them was categorized as high-risk. Furthermore, the one supplier categorized as high-risk in 2023 was no longer a high-risk supplier in 2024. This was confirmed through a third-party audits.

Assessment Scope of Upstream Supplier(Tier 2 supplier and beyond)

(KPI 1)% of suppliers assessed(number of Tier 1 suppliers)

| Year | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| Results | Results | Results | Results | Target | |

| % of suppliers assessed(number of suppliers assessed)* | 97% (279) |

100% (67) |

100% (860) |

100% (35) |

100% |

| Geographical scope | Global Headquarters, EMEA Regional Headquarters and some suppliers | All significant Tier 1 suppliers in all regions | All Tier 1 suppliers in all regions | All significant Tier 1 suppliers in all regions | |

- *% of suppliers assessed = number of suppliers assessed / total number of suppliers in scope of assessment

(KPI 2)% of strategic suppliers assessed(number of Tier 1 suppliers)

| Year | 2021 Results |

2022 Results |

2023 Results |

2024 Results |

2025 Target |

|---|---|---|---|---|---|

| % of strategic suppliers assessed (number of suppliers assessed) | 100% (17) |

100% (23) |

100% (24) |

100% (23) |

100% |

Issues of high-risk suppliers found through third-party audits

In 2024, we conducted third-party audits of four companies. The suppliers took the following corrective measures during the year and we confirmed that the corrections had been completed.

| Area | Examples of issues | Examples of corrective actions |

|---|---|---|

| Occupational health and safety | The fire prevention certificate for the warehouse area has expired. | The fire prevention certificate was renewed. |

| Improper storage of waste liquid scheduled for disposal. | Training was conducted for relevant personnel. | |

| No eyewash stations were installed in areas where hazardous materials are handled. | An eyewash station was installed. | |

| The scope of the fire drill was not all employees | All employees were involved in the fire drills. | |

| The emergency exit signs were blocked by cartons and could not be seen. | Signs indicating the emergency exits were installed in visible locations. | |

| Human rights | Long employee working hours were occurring. | Working hours were thoroughly managed by site supervisors. |

| The environment | No issues | |

Partnership with suppliers

Declaration of Partnership Building

Shiseido announced its Partnership Building Declaration in March 2023. This is a statement made by a representative of a purchasing company detailing the company’s commitment to cooperation and mutual prosperity throughout the supply chain.

Promoted by the Small and Medium Enterprise Agency in Japan, the objective is to achieve sustainable growth throughout the supply chain by strengthening partnerships with suppliers and influencing upstream suppliers through direct transaction suppliers. We endeavor to increase mutual prosperity with suppliers by preventing business practices that hinder partnerships and improving business customs.

Declaration of Partnership Building

Supplier Performance Evaluations

Once a year, Shiseido evaluates the performance of its suppliers from the perspectives of QCDST* and sustainability.

Evaluation results are provided to suppliers as feedback during business meetings and other occasions, and along with requesting improvements, results are also reflected in our category strategy.

Evaluation weight for sustainability criteria is 20% of the total, and evaluation criteria includes results such as supplier self-assessment.

- *Quality, Cost, Delivery, Service, Technology

Shiseido Suppliers’ Day

Shiseido invites the top management of suppliers that have shown high performance to Shiseido Suppliers' Day, in order to share information about Shiseido's Medium-Term Strategy, policies on procurement activities and expectations of suppliers. 2021 was the first time the Shiseido Suppliers' Day was held online globally. As part of this event, we requested the understanding and cooperation of suppliers, explaining our sustainability medium-term targets and action, in addition to describing what we expect from them in terms of human rights, the environment and society.

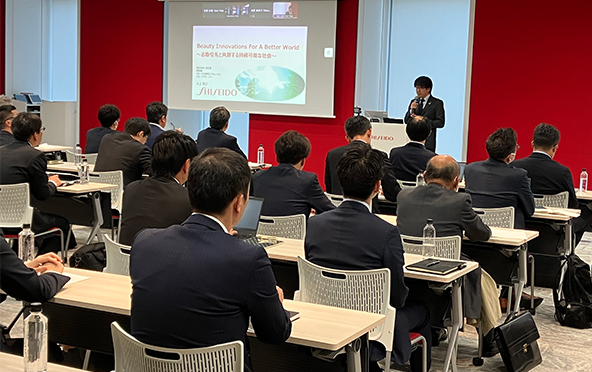

Briefing Sessions on Procurement and Sustainability Policies

To keep pace with the changing times and respond to social requirements, Shiseido considers it important to communicate our concept of procurement with business partners in a timely and accurate manner.

Therefore, with the aim of widespread dissemination of the procurement policy, the procurement departments in the global headquarters and China Regional Headquarters hold an annual Supplier's Day to share purchasing activities and strategies with suppliers.

Taking this opportunity, our global headquarters procurement department promulgates Shiseido’s procurement policy, various tasks, and requests in the fields of raw materials, packaging, and indirect materials, and responds to questions and requests from business partners.

To ensure responsible procurement through an engagement with our suppliers, since 2023, we have been holding sessions not only in Japan but also at some overseas offices to explain our requests to the suppliers as well as our policies on human rights and the environment for sustainable procurement.

In 2024, we held a briefing on procurement for approximately 300 business partners in Japan, explaining international sustainability trends, our medium- to long-term sustainability goals and the promotion of the Supplier Assessment Program. Furthermore, we held a ceremony to present letters of appreciation to suppliers who have shown great performance in terms of the Supplier Assessment Program. To strengthen supplier engagement, we will continue to hold such initiatives as well as the sessions.

The Briefing Session on Procurement

Global Procurement Collaboration and Education for Buyers

Global Procurement Collaboration

We regularly host meetings with procurement leaders from each of our global facilities. At these meetings, policies and strategies related to important themes such as sustainability are discussed to promote close coordination.

In addition, once a year we hold a Shiseido Procurement Summit (SPS) where Procurement leaders from each region gather in one place. Through this Summit, we are further promoting the global implementation of sustainability activities. We held it in Tokyo in 2023 and in Shanghai in April 2024.

Shiseido Procurement Summit held in China

Education for Buyers

To implement sustainable and responsible procurement across the Shiseido Group, Shiseido provides various training directed at employees of procurement departments from perspectives including human rights, occupational health and safety and the environment.

Education Provided for Members of Procurement Department

| Year | Theme | Participants |

|---|---|---|

| 2022 | Internal explanatory meeting about Shiseido Group Procurement Policy | Procurement Department in all regions |

| EcoVadis buyer training*1 | Procurement Department at the Global Headquarters, China & Travel Retail Regional Headquarters, Affiliate in APAC Regional Headquarters, the EMEA Regional Headquarters, Americas Regional Headquarters | |

| EcoVadis program kickoff*2 | Procurement Department in all regions | |

| 2023 | DE&I: Session to exchange views on male childcare leave | Procurement Department at the Global Headquarters |

| DE&I: Workshop on communicating with others with different values and cultures | Procurement Department at the Global Headquarters | |

| Seminar on challenges related to sustainability and Shiseido's sustainability strategy | Procurement Department at the EMEA Regional Headquarters | |

| Seminar on climate change and carbon neutrality | Procurement Department at the China & Travel Retail Regional Headquarters | |

| Workshop on supplier human rights issues and risk management*3 | Procurement Department at the Global Headquarters | |

| 2024 | DE&I: Study group on balancing nursing care and work | Procurement Department at the Global Headquarters |

| DE&I: Session to exchange views regarding people with disabilities | Procurement Department at the Global Headquarters | |

| Climate change workshop | Procurement Department at the EMEA Regional Headquarters | |

| Indirect supplier assessment training | Procurement Department at the Global Headquarters, China & Travel Retail Regional Headquarters, Affiliate in APAC Regional Headquarters, the EMEA Regional Headquarters, Americas Regional Headquarters |

|

| Internal explanatory meeting about the Sustainable Packaging Development Policy*4 | Procurement Department at the Global Headquarters, China & Travel Retail Regional Headquarters, the EMEA Regional Headquarters, Americas Regional Headquarters |

- *1:Training on EcoVadis and the Supplier Assessment Program has been regularly provided to new staff and buyers at global headquarters and in each region since 2022.

- *2:We held a global meeting to confirm the purpose of supplier assessment, KPIs, and the roles and responsibilities of employees in charge of the assessment.

- *3:Actual examples were used for discussions about the roles and actions of each person and how the company should respond, taking into account the Shiseido Group Procurement Policy.

- *4:The meeting provided buyers with an opportunity to enhance their understanding of the sustainable procurement of paper and plastics, our policy on traceability, and their respective roles.

Programs to Improve ESG Performance of Suppliers

Shiseido carries out the following training and other programs periodically to increase the ESG performance of its suppliers and deepen their understanding of our human rights and environmental policies.

| Item | Target | Details |

|---|---|---|

| Explanation of Shiseido Group Procurement Policy | All suppliers |

|

| Feedback on self-assessment results | All suppliers |

|

| E-learning (EcoVadis Academy) |

Strategic suppliers |

|

In addition, we have recently held the following explanatory meetings and seminars. We are working out a plan to enable us to provide more suppliers with training programs.

| Item | Target | Details |

|---|---|---|

| EcoVadis explanatory meeting(2021―2022) | All suppliers |

|

| CDP explanatory meeting(May 2023) | Suppliers in Japan |

|

| Sustainability Policy Briefing(2023 and 2024) | Suppliers in Japan(November 2023) Suppliers in China (June 2024) |

|

| EcoVadis Score Improvement Seminar(June 2024) | Suppliers in Japan that have newly joined EcoVadis and suppliers under a specific EcoVadis score |

|

| Procurement Briefing (November 2024) | Suppliers in Japan |

|

| EcoVadis Score Improvement Seminar (May 2025) | Suppliers in Japan that have newly joined EcoVadis and suppliers under a specific EcoVadis score |

|

Taking Part in Initiatives Related to Responsible Procurement

Shiseido has been a member of the Responsible Beauty Initiative (RBI) since 2022. RBI is an initiative related to sustainability in the cosmetics industry. Through the sharing of best practices among member companies and discussions about issues that affect the entire industry, RBI works to improve sustainability throughout the supply chain. The Vice President of the Procurement Department of the EMEA Regional Headquarters is a member of the RBI's steering committee, which is its highest decision-making body.

ABOUT US

-

Who we are

-

History

-

Profile

-

Governance

-

Quality Management

-

Supply Network

-

Region/Business

BRANDS

-

Prestige

-

Premium

-

Inner Beauty

-

Life Quality Makeup

SUSTAINABILITY

-

Strategy / Management

-

Society

-

Environment

-

Governance

-

Reports / Data

-

Related Information

INNOVATION

-

Research and Development

-

Research Areas

-

Research outcomes

-

Product safety

-

Product Development Policy

-

Initiatives for doctors and researchers

CAREERS

-

DISCOVER OUR WORLD OF OPPORTUNITY

- Shiseido careers

INVESTORS

-

IR Library