- Home

- SUSTAINABILITY

- Environment

- Developing Sustainable Products

Developing Sustainable Products

At Shiseido, we prioritize quality and safety above all else, ensuring that consumers can use our products with peace of mind. In addition to strict compliance with laws and regulations, we have established our own high-level standards to maintain and manage quality.

With high quality and safety as our foundation, we are committed to creating new value to meet and support the desires of consumers who wish to be beautiful.

DYNAMIC HARMONY, the unique Research & Development philosophy that was formulated when Shiseido was founded, reflects our commitment to creating new forms of beauty by combining contrasting forces: Eastern wisdom and Western science. One of our approaches is to establish Premium/Sustainability, through which we challenge ourselves to create unique sustainable value that is distinctive to Shiseido.

Through manufacturing based on the principles of green chemistry, we contribute to reducing environmental impact throughout the product lifecycle. We also take responsibility for our business activities that utilize the Earth's limited resources and aim to achieve a circular economy.

Reducing Environmental Impact Based on Our Product Development Policy and the Concept of Product Lifecycle

Shiseido has applied its extensive research expertise in dermatology and material science, accumulated over more than 100 years, to develop and deliver safe, high-quality products and services to society. To sincerely address the health of people and the environment, we have disclosed our Product Development Policy that outlines our approach to product development (formulas and packaging) and the use of socially controversial ingredients.

Since cosmetics often contain naturally derived ingredients, sustainable and responsible procurement and use of raw materials are critical issues from the perspective of environmental conservation. Based on a product lifecycle approach, we are committed to developing formulas/ingredients, packaging, and circular recycling models that promote the effective use of limited resources, environmental considerations, addressing climate change, and minimizing the impact on ecosystems.

Click here for Product Development Policy (About Ingredients/Formulas)

Formulas/Ingredients

Our Approach for Formulas/Ingredients

As part of Shiseido's commitment to sustainable research and development, we focus on formulation development that considers not only safety, quality, functionality, and sensory experience for the human body but also environmental impact, biodiversity, and social effects. This approach contributes to creating value for consumers.

To reduce environmental impact, we use biomass-based (naturally derived) and recycled materials and ingredients, striving to create circular value. Our company establishes its own standards based on the Formula Development Policy and Ingredients Policy, which include not only strict safety measures but also environmental considerations and ethical perspectives. By applying the principles of green chemistry, we are challenging ourselves to create unprecedented new value. More information about our ingredients is disclosed on our website.

UV Care and Suncare Innovation

Climate change affects atmospheric circulation. Changes in atmospheric environment and currents affect the location and amount of clouds, and this is expected to increase consumers' UV exposure in the future.*1

Prompted by the greater importance of UV care, we are continuing to develop suncare technologies, an area we have been active in for over 100 years, so that we can continue to provide new innovative UV solutions. Exposure to UV rays for extended periods of time causes spots and wrinkles on the skin—symptoms of photoaging. By providing technologies and products designed to protect consumers' skin and health against powerful UV rays, we believe we can reduce the impact of photoaging and improve the quality of life simultaneously, which leads to the creation of social value.

For example, in 2024, we launched suncare products under our suncare brand ANESSA and brand SHISEIDO, featuring the newly developed “Automatic Veil Technology.” This innovative technology automatically repairs unevenness or gaps in suncare products caused by facial movements, thereby enhancing protection performance and user experience.

SHISEIDO Expert Sun Protector Lotion

ANESSA PERFECT UV SUNSCREEN SKINCARE MILK

In its quest for a Next-Generation Mineral Sunscreen Technology, Shiseido, in collaboration with Tokyo University of Agriculture and Technology, has developed the world’s first technology*2 in a mineral sunscreen formulation*3 that triggers UV scattering agents to achieve their optimal dispersion state on the skin. The results of this research received the top award at the IFSCC*4 Congress, garnering high acclaim as a next-generation cosmetics technology. We will continue to leverage technical innovation to provide suncare products that achieve a high level of both UV protection and excellent usability, and that also minimize the health impacts of UV rays.

- *1:According to an announcement by the Japan Agency for Marine-Earth Science and Technology.

- *2:The world's first technology that improves the dispersibility of powder through the evaporation of volatile components after application in a suncare formulation using only UV scattering agents (Based on a Clarivate Analytics Japan survey in August 2024)

- *3:A formulation that ensures UV protection solely through UV scattering agents

- *4:The International Federation of Societies of Cosmetic Chemists. The world's largest and most prestigious research conference for cosmetics technology. Shiseido won the top award for the Podium Presentation Applied Research category.

We recognize the need for companies to appropriately address the impact on ecosystems due to ingredient runoff, especially since suncare products are often used in marine environments.

Shiseido examines the impact of UV filters in our suncare products on coral*5 by combining research on their ecological effects, conducted in collaboration with universities and research institutions, with simulation*6 results of their concentration distribution in the ocean. These findings are utilized in ingredient selection and in designing formulas that consider the impact on coral, and they are applied to suncare products such as brand SHISEIDO and ANESSA.

In addition, in 2023, in order to evaluate the impact of cosmetic ingredients on marine ecosystems, we began a partnership agreement with Innoqua Inc., a start-up company with proprietary technology that reproduces ecosystems in an aquarium. The aquarium can reproduce possible future environmental change scenarios, including ‘rising seawater temperatures’, which are predicted to have a tremendous impact on marine life. This allows us to evaluate the impact of various cosmetic ingredients, such as those used in sunscreen, on the entire marine environment, including coral and other organisms.

Artificial marine ecosystem reproduced in an aquarium using environmental transfer technology developed by Innoqua Inc.

- *5:Egg-laying size groups of coral, excluding those in the planktonic larval and juvenile stages.

- *6:Utilizing the Tokyo Bay risk assessment model developed by the National Institute of Advanced Industrial Science and Technology.

Click here for Corporate website: Research on Sustainability

Click here for Brand website: SHISEIDO

Click here Brand website: ANESSA (In Japanese only)

Click here for the news release regarding Innoqua Inc. (In Japanese only)

Proper management of chemical substances

In light of growing societal concern regarding the safety and environmental impact of chemical substances, as well as stricter regulations, particularly led by the EU, we are strengthening our commitment to responsible chemical substance management. From the formulation development stage of cosmetics, we are minimizing the use of SVHC (Substances of Very High Concern) and controversial ingredients. In addition, we are actively promoting the replacement of materials with plant-derived ingredients and the adoption of alternative processes and technologies utilizing green chemistry. For ingredients that are likely to be released into the environment after product use by consumers, we are analyzing their dynamics in the environment and enhancing our understanding of their impact on the ecosystem.

For newly developed ingredients, we refer to both domestic and international safety assessment guidelines while establishing our own strict standards. Additionally, we assess safety without conducting animal testing by utilizing alternative testing methods and other approaches in line with OECD Guidelines for the Testing of Chemicals. We continuously monitor global trends in chemical regulations and advanced technologies, including those in Japan and Europe. We comply with safety and environmental regulations in each country and region, while also ensuring a comprehensive and rigorous understanding of the impacts and management across the entire lifecycle of cosmetic ingredients—ranging from ingredient safety and material selection to manufacturing processes and post-use biodegradability. Through these efforts, we strive to deliver safe and sustainable products.

No Animal Testing

We strive to provide safe and effective products to consumers while complying with cosmetics regulations and respecting the principles of animal protection. For more than 40 years after we established a safety research department in 1963, we continued to study alternative methods that do not involve animal testing. In 2013, we abolished animal testing entirely* and shifted to a safety assurance system that does not use animals.

We have established a safety assurance system with our unique strict standards. Working together with external stakeholders, we are striving to establish alternative methods, developed on our own or jointly with other companies, as official methods.

In February 2023, we announced our involvement in the newly launched International Collaboration on Cosmetics Safety (ICCS). The ICCS is a global project involving manufacturers, suppliers, industry associations, and animal protection organizations whose goal is to promote and implement animal-free safety assurance in the development of cosmetics and personal care products.

Shiseido will promote and implement the safety assurance of cosmetics without animal testing through the sharing of technologies and knowledge about alternative methods of animal testing, discussions and collaboration with related companies and organizations, and responding to the regulations of each country and region.

- *Except when required by governmental and regulatory authorities.

Innovation with an Eye toward the Future

In 2022, Shiseido joined the MATSURI project, a cross-industry project exploring bioeconomic solutions led by the CHITOSE Group. More extensive use of algae is expected to contribute to lower CO2 emissions in future, where algae products can replace fossil-derived raw materials. In 2023, Shiseido invested 1.0 billion yen in the CHITOSE Group and signed a strategic collaboration agreement focused on R&D with the Group. The purposes of this initiative include the development and mass production of cosmetics and container raw materials using algae, as well as the development of raw materials that can be used in the food industry. As a MATSURI project member, we unveiled two skincare product prototypes using ingredients derived from algae at the Japan Pavilion of Expo 2025 Osaka, Kansai, Japan, which started in April 2025. The products were developed on the theme of the beauty of life which circulates.

To maximize the potential of algae, we will work together with MATSURI Project partner companies in ending the use of fossil resources for cosmetics.

Vision products

(Cosmetics prototypes)

Click here for the News release about MATSURI (In Japanese only)

Initiatives with External Institutions

Granting Technology License to Toyo University for Environmental Impact Reduction

In March 2020, Shiseido became the first WIPO GREEN* partner company from the cosmetics industry. In 2022, we granted Toyo University a license to use our low-energy manufacturing technology, which is listed in the WIPO GREEN database. In 2022, the university developed a prototype of an environmentally friendly product that uses the extract from boysenberries, a local specialty of Tatebayashi City, Gunma Prefecture. The product began to be sold via crowdfunding in 2023.

- *The World Intellectual Property Organization (WIPO) is a specialized agency under the United Nations, responsible for developing international intellectual property systems. WIPO GREEN is an international framework for promoting innovation in environment-related technologies, and has more than 150 partner companies. As of April 2024, Shiseido had licensed out 11 patented technologies registered in the WIPO GREEN database.

Sustainable Packaging

Marine plastic pollution and waste reduction are urgent global environmental issues that require immediate action. The 'Global Plastics Treaty,' currently under discussion, is trying to adopt a lifecycle approach that encompasses material production, product design, consumer use, waste management, and recycling, calling on companies to take proactive measures.

Since the launch of our first refillable product in 1926, we have strived to provide consumers with beauty products while simultaneously reducing our environmental footprint through various initiatives, such as the elimination of chlorofluorocarbons from aerosol products and the recycling of glass containers.

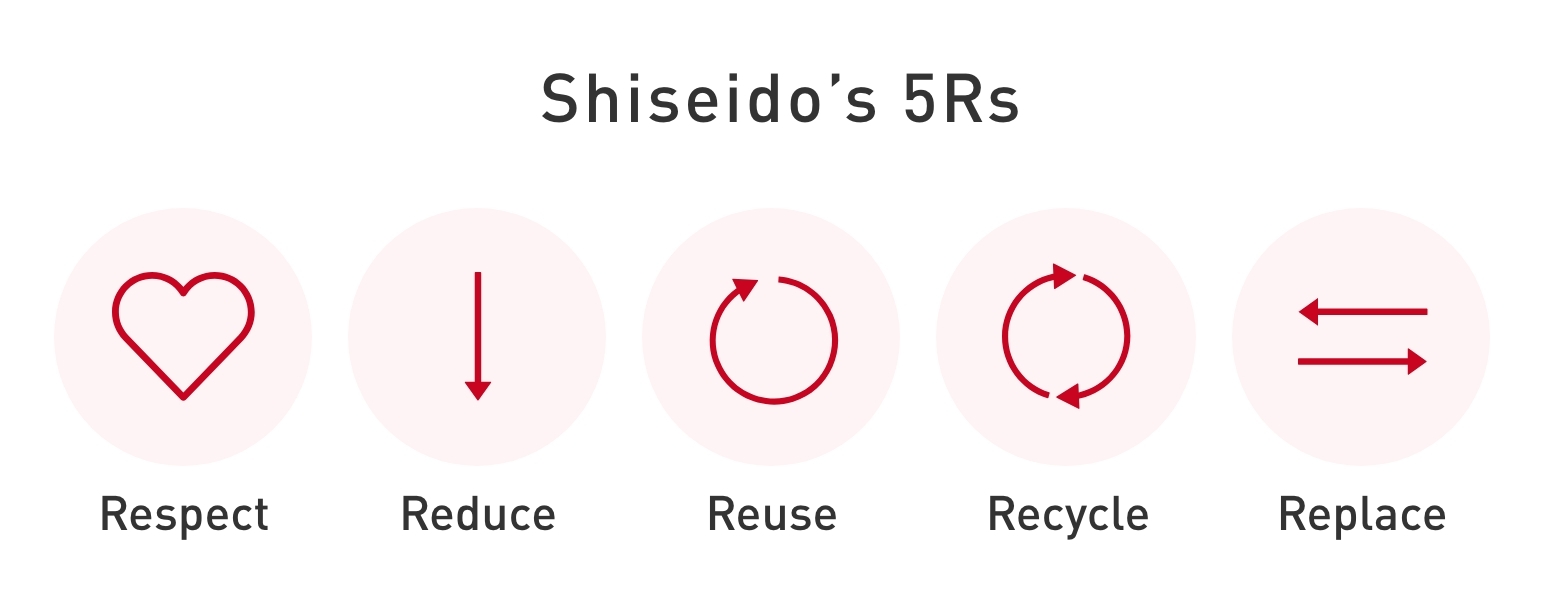

In 2020, we developed the Shiseido 5Rs packaging development policy*1 to ensure that resources are used in the most efficient ways and to realize a circular economy. We are working toward our goal of 100% sustainable packaging*2 by 2025. Specifically, we are adopting refillable packaging to promote reuse, and mono-material packaging to improve recyclability. We have also reviewed materials including using post-consumer recycled (PCR) and bio-based materials, and reduced packaging weight.

As of the end of 2024, 76% of our packaging had been switched to sustainable packaging.*3

To further strengthen our global sustainability initiatives, our goal is to increase the proportion of recycled materials (post-consumer recycled: PCR)*4 used in plastic packaging made from PET (polyethylene terephthalate) to 30% by 2030. Additionally, we are expanding the use of PCR and bio-based materials, targeting these materials to collectively account for 15% of our total primary packaging, including glass, PP (polypropylene), and PE (polyethylene).

Our efforts alone are not enough to realize a circular economy. We need to work with multiple stakeholders, including other industries and companies, suppliers, consumers, retailers, and governments. We intend to play a more active role throughout our value chain by working together with stakeholders and becoming involved in initiatives.

- *1:Packaging development policy: respect, reduce, reuse, recycle, and replace.

- *2:For plastic primary packaging, on a design basis.

- *3:Amount of plastic packaging used in Japan in 2024 (including estimates): Approximately 8,100 t.

- *4:Refers to materials recovered and processed from used products so that they can be reused as components or raw materials for new products.

Initiatives for Sustainable Packaging

Reduce and Reuse

Under the premise that the resources on the Earth are finite, Shiseido promotes global initiatives to reduce plastic usage and environmental impact in accordance with the "Shiseido 5Rs" policy. These initiatives include such as optimizing container sizes to realize sustainability while maintaining the prestigious image, lightweighting containers, and launching refillable containers. Refillable packaging not only reduce the resources used, but also encourages the reuse of primary containers, thereby decreasing the total amount of plastic used in packaging. Evaluations conducted through Life Cycle Assessment (LCA) have shown that compared to single-use primary containers, the use of refillable containers leads to lower resource usage waste generation, and significantly reduces CO₂ emissions. Since the launch of our first refillable product in 1926, we have provided refillable packaging in a wide range of product categories, including skincare and makeup. In 2024, we offered refillable packaging for about 790 stock keeping units (SKUs) within 31 brands globally in an effort to reduce the amount of plastic and ultimately the environmental footprint.

In 2023, the brand SHISEIDO, which operates in 90 countries and regions around the globe, became the first company to sell cosmetics using containers made with LiquiForm® technology,* which is a one-step technology for manufacturing bottles and filling them with liquid content.

- *The new packaging technology was developed chiefly by Amcor. Shiseido worked with Yoshino Kogyosho, a company that has put the technology to use, to jointly develop cosmetic packaging.

LiquiForm®

Key Initiatives for Product Launched in 2024

Shiseido is committed to reducing plastic waste by adopting refillable packaging. In 2024, for example, within the skincare category, we launched refillable products for SHISEIDO creams, Clé de Peau Beauté serums and eye creams, and ELIXIR serums. In the suncare category, we introduced refillable products for ANESSA serums. In the makeup category, we offer refillable products for MAQuillAGE foundation serums. In the fragrance category, ISSEY MIYAKE PARFUMS offers refillable products and uses wooden caps instead of plastic for the product lids.

We are committed to reducing glass usage. In 2024, in collaboration with our supplier, we successfully developed lighter glass bottles that maintain the same durability as previous containers. The SHISEIDO ULTIMUNE™ Power Infusing Serum launched in March 2025 feature glass containers that are 20% lighter than their predecessors.

SHISEIDO Vital Perfection Uplifting and Firming Advanced Cream

Clé de Peau Beauté THE SERUM II

ELIXIR The Serum aa

MAQuillAGE Essence Liquid EX

ANESSA Skin Serum

ISSEY MIYAKE PARFUMS Le Sel d'Issey

External Evaluations

The packaging designs and sustainable container initiatives of SHISEIDO and Clé de Peau Beauté were recognized at the WorldStar 2024 Competition, hosted by the World Packaging Organisation. Both brands' designs received WorldStar Awards not only for their refined aesthetics and premium user experience, but also for their use of refillable containers, which contribute to the reduction of environmental footprint.

WorldStar Award-winning products from SHISEIDO (left) and Clé de Peau Beauté (right)

Recycle

To realize a circular economy, it is important to select materials and design products with the reuse of resources in mind.

To reduce our consumption of single-use plastic, we are developing packaging made from a material that can be more easily sorted and recycled after use without compromising the quality of the packaging’s design.

In 2024, a number of our major brands launched products with packaging that is easier to recycle. For example, the recyclability of the ELIXIR tube packaging has been improved by switching from a multi-material structure to a mono-material design.

ELIXIR Day Care Revolution Tone Up + aa

Replace

To mitigate climate change and plastic pollution, we are focusing on the research of post-consumer recycled (PCR*1) materials, plastic alternatives, and bio-based materials with low environmental impact—and promoting their use. For example, packaging of some Clé de Peau Beauté and ELIXIR products is made from recycled plastic.

ELIXIR uses over 72% recycled PET in the bottles of its facial lotion and emulsion*2. In January 2025, IPSA launched a new facial lotion and its container is approximately 50% chemically recycled PET, whose quality is comparable to virgin PET. This newly developed container combines high environmental performance with an aesthetically refined design. In 2024, THE GINZA released a hand cream that uses PCR-based PE for its cap for the first time at Shiseido.

IPSA THE TIME R AQUA

The use of bio-based plastics is also increasing across our various brands, beginning with SHISEIDO makeup and sun care products.

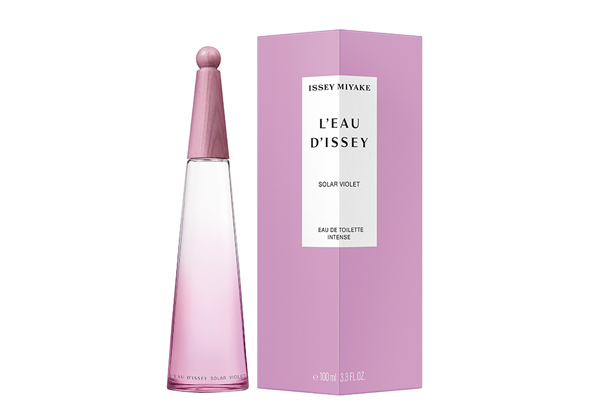

In addition, the adoption of containers made with recycled glass is increasing. These containers are now widely used not only by major brands, such as SHISEIDO and Clé de Peau Beauté, but also for fragrance products from ISSEY MIYAKE PARFUMS and narciso rodriguez, as well as by ELIXIR and BAUM.

ISSEY MIYAKE PARFUMS L’eau d’Issey Solar Violet Eau De Toilette Intense

Point of Sale Materials (POSM) used at retail stores, such as drug stores, and counters that are made from plastic will also be replaced with paper alternatives in due course to further reduce the amount of plastic we use.

- *1:Refers to materials recovered and processed from used products so that they can be reused as components or raw materials for new products. PCR stands for Post-Consumer Recycled.

- *2:For facial lotion and emulsion launched after September 2022

POSM

At Shiseido, we published the POSM Eco Design Guideline in 2023 for the purpose of reducing the environmental impact related to the lifecycle of promotional materials, including in-store display tools and shopping bags. Based on the guideline, we promote the development of POSM materials in line with Shiseido's 5Rs. We will work with our stakeholders to reduce our environmental impact in not only the manufacturing of our products, but also in promotional materials.

Switching to paper for POSM

Secondary Packaging

In addition to the improvement of primary packaging, which directly protects the contents of the product, Shiseido is also advancing environmental measures for secondary packaging, which wraps the primary packaging. For example, our ANESSA and ELIXIR brands are switching from plastic to sustainably certified paper for their secondary packaging.

Switching to paper for the secondary packaging

Tertiary Packaging

Shiseido sets strict standards not only for primary and secondary packaging but also for tertiary packaging, which protects products from contamination during production and transportation. To conserve resources, we began reducing tertiary packaging, such as protective boxes and pillow pouches since 2023, thereby helping to minimize both plastic waste and paper consumption. In 2024, we achieved reductions for 91 SKUs in Japan, focusing on key brands such as MAQuillAGE and INTEGRATE.

Participation in Related Initiatives

R Plus Japan Ltd.

To play a part in solving the global plastics recycling challenge, Shiseido invested in R Plus Japan in 2022 and engaged in recycling used plastics. The Vice President of the Procurement Department at Global Headquarters attends the monthly meetings with participating companies to strengthen the collaboration. By bringing together companies across the plastic packaging industry—from monomer and polymer manufacturers to packaging producers, trading, food, and beverage companies—R Plus Japan aims to commercialize an efficient, low-environmental impact recycling technology by 2030.

EcoBeautyScore

The EcoBeautyScore Association is a not-for-profit organization whose primary goal is to develop a common environmental impact scoring system for cosmetic products. Developed with more than 70 cosmetics players across 46 countries, the system helps to bring more transparency to consumers while encouraging brands to adopt more sustainable practices. Shiseido has been a member since 2022 and continues to support the EcoBeautyScore Association as it prepares to launch to consumers in 2025.

Actions Toward Consumer Needs

As consumer awareness of environmental and social issues is increasing and becoming more personal, more consumers value not only product quality and usability, but also the safety of raw materials, environmental impact, and corporates' efforts to address social issues, such as human rights, when choosing products and brands. In response, Shiseido is advancing initiatives to address these fundamental environmental and social challenges across all its brands while also promoting brand-specific sustainability activities that reflect the unique concept of each brand.

Among these efforts, Shiseido has positioned several distinctive brands to have sustainability at the core of their value proposition, specifically targeting consumers who are highly conscious of environmental and social issues.

BAUM

BAUM was established to celebrate and honor our coexistence with trees. Over 90% of its cosmetics contain nature-derived ingredients. In 2024, the brand incorporated Hinoki Water into five of its core skincare products. Hinoki Water is a new tree-derived ingredient extracted from Japanese cypress grown in specially partnered forests. BAUM also uses refillable packaging and wooden parts made from upcycled wood from furniture scraps. Some containers also feature plant-based or recycled plastics, in addition to recycled glass, reflecting the brand's commitment to sustainable products.

BAUM HYDRO ESSENCE LOTION n. Left: main container, Right, refillable container

ISSEY MIYAKE PARFUMS

ISSEY MIYAKE PARFUMS is a brand developed in 1992 through a collaboration with Japanese designer Issey Miyake and Miyake Design Studio. ISSEY MIYAKE PARFUMS is designed to reconnect people with nature. Revealing the richness, beauty and surprises of nature to move and invite to see the world from a new angle. The brand offers fragrances with high part of natural ingredients, packaging made from up to 20% recycled glass and certified paper.

ISSEY MIYAKE PARFUMS L’eau d'Issey, L’eau d'Issey pour homme

Initiatives for Resource Recycling

To realize a decarbonized society and a circular economy, it is necessary to add value to products and materials that have completed their roles once again and to reuse them as recyclable resources repeatedly in society.

Shiseido is working to establish a scheme for collecting used plastic cosmetic containers through retail stores, leveraging a wide range of interactions with consumers and business partners. This initiative aims to secure sustainable, high-quality resources for the future and implement a circular economy in society. By fostering awareness that used containers can become resources for new products and encouraging behavioral change across society, we aim to enhance the resilience of resource procurement from a long-term perspective.

“BeauRing®” Circular Model Project for Plastic Cosmetics Containers

In April 2023, we introduced the “BeauRing®” project—a circular model project to collect plastic containers and recycle them into new ones for reuse.

We launched a pilot project in partnership with POLA ORBIS HOLDINGS INC. to collect used plastic containers at some cosmetic stores in Yokohama City. As well as driving in-house initiatives, we are encouraging other companies to join the project and examine the circular model that can contribute to the creation of a sustainable world in which consumers use cosmetics with a more positive mindset.

「BeauRing®」BOX、「BeauRing」logo

Click here for Circular Model Project “BeauRing” (In Japanese only)

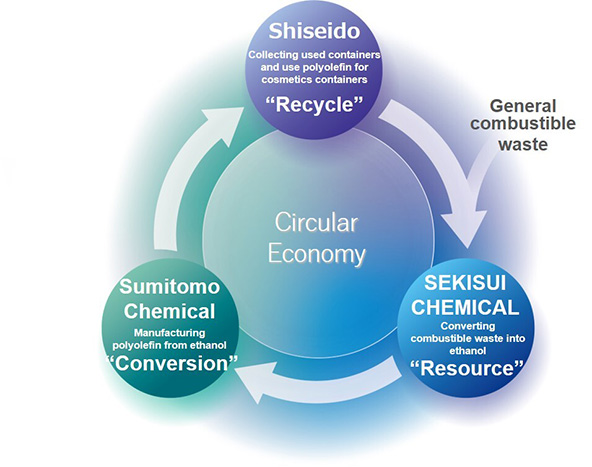

Collaborating to Build a Circular Model for Plastic Cosmetics Containers

In 2022, Shiseido initiated a collaboration with SEKISUI CHEMICAL CO., LTD. and Sumitomo Chemical Co., Ltd. to develop a circular program for collecting and recycling plastic cosmetic containers without the need for sorting and pre-washing. Currently, Shiseido is conducting trials to recycle containers collected through BeauRing box into new cosmetic containers, and the process of converting the collected containers into ethanol has been successfully completed. Moving forward, we plan to use this ethanol to produce polyolefin, which will then be recycled into cosmetic containers. Through this initiative, the three companies aim to work together and encourage participation from related industries and companies to realize a circular economy.

Three companies collaborating in building a circular model

Recycling Initiatives in China

In 2023, Shiseido launched a joint recycling initiative in China with a packaging material supplier. We recycle used plastic containers for the cosmetics of the AUPRES brand, which we market in China. The amount of plastic recycled in 2024 increased to nearly nine times compared to the previous year.

The containers are transformed into recycled materials through the supplier's recycling technology and are utilized for products such as desks, chairs, and novelty items.

ABOUT US

-

Who we are

-

History

-

Profile

-

Governance

-

Quality Management

-

Supply Network

-

Region/Business

BRANDS

-

Prestige

-

Premium

-

Inner Beauty

-

Life Quality Makeup

SUSTAINABILITY

-

Strategy / Management

-

Society

-

Environment

-

Governance

-

Reports / Data

-

Related Information

INNOVATION

-

Research and Development

-

Research Areas

-

Research outcomes

-

Product safety

-

Product Development Policy

-

Initiatives for doctors and researchers

CAREERS

-

DISCOVER OUR WORLD OF OPPORTUNITY

- Shiseido careers

INVESTORS

-

IR Library