- Home

- ABOUT US

- Shiseido Talks

- With Passion, Urgency, and Swift Action: Involving Others to Drive Innovation and Move Towards a Circular Society

With Passion, Urgency, and Swift Action: Involving Others to Drive Innovation and Move Towards a Circular Society

~Shiseido participating in the industrialization project "MATSURI" for sustainability.~

February 9, 2024

Shiseido has set a goal for 2030 and it is "to create a sustainable world where everyone can enjoy a lifetime of happiness through the power of beauty." To realize a circular society, the company is actively engaged in the development of technologies and business models. As part of their strategic actions, Shiseido is participating in an innovative project called MATSURI*1 (Microalgae Towards Sustainable and Resilient Industry), a world-first collaborative effort led by CHITOSE Group*2. The project aims to implement a new industry based on microalgae, replacing the petroleum industry. This article features interview with Nozomi Oguchi, Head of the Raw Material Development Department in the Brand Value Development Research Institute and Yuji Ito from the Raw Material Development Group so that we can learn more about their challenges and endeavors in developing new technologies for the future.

History and plans of Shiseido’s participation in MATSURI.

| April 2022 | Joined MATSURI as a Corporate Partner |

| April 2023 | Visited the CHITOSE Carbon Capture Central (C4) microalgae production facility in Kuching, Malaysia and participated in the opening ceremony |

| July 2023 | Made a 7million USD investment in CHITOSE Group and entered into a strategic partnership agreement |

| September 2023 | Commenced component analysis of dried algae |

| 2024 | Planned development of cosmetic ingredients |

| 2025 | Planned completion of prototype products |

| 2030 | Planned product commercialization |

―Could you give us an overview of the MATSURI project?

Ito: MATSURI is an ambitious project with a grand vision - to achieve a sustainable society that will endure for a thousand years. It aims to accomplish this by completely replacing the "fossil resources" (such as petroleum, coal, and natural gas) that are crucial for our society and economy but raise concerns like climate change and resource depletion, with resources derived entirely from "microalgae."

This groundbreaking initiative calls for specialized knowledge and expertise at every step, from developing advanced microalgae production techniques and designing cutting-edge facilities, to analyzing components, refining processes, and creating final products. MATSURI sets its sights on expanding into diverse industries, forging collaborations with various companies and organizations to establish an entirely new industrial structure.

The project's essence lies in forging connections that transcend industry boundaries, driven by a shared commitment to society and the future of our planet. Beginning in Japan, the aim is to leverage the technological expertise and collective wisdom of each participating company to overcome challenges together. It is an immensely dynamic and inspiring endeavor.

Yuji Ito, Brand Value Raw Material Development Group of the Brand Value R&D Institute

―What are the reasons for Shiseido’s decision to participate in MATSURI?

Secondly, MATSURI's microalgae production system stands out for its eco-conscious approach. The facility in Malaysia directly harnesses and utilizes CO₂ emitted by a neighboring coal-fired power plant, resulting in a significant reduction in its overall carbon footprint. This innovative and environmentally friendly system showcases MATSURI's dedication to sustainability and sets an inspiring example for the industry.

The challenges of mass-producing microalgae are undeniable, including the constant risk of contamination which are the growth of competing algae and bacteria. While some may consider using artificial lighting to enhance photosynthesis as a potential solution, it introduces a new conundrum - the unintentional emission of additional CO₂. Balancing the need for stable production while minimizing environmental impact is an ongoing pursuit for MATSURI.

Upon learning about the project at an academic conference, I was immediately compelled to visit the office of CHITOSE Group and meet its representative, Dr. Tomohiro Fujita. His vision, rooted in the intersection of technology and business, was nothing short of inspiring. His passionate words resonated deeply within me, prompting me to swiftly report to Director Oguchi, exclaiming, "We simply have to be a part of this extraordinary endeavor!" This vibrant and dynamic project is sure to captivate the imagination of all those who yearn for progress and sustainable solutions.

Nozomi Oguchi, Raw Material Development Department Director of the Brand Value R&D Institute Development Acceleration Center

Oguchi: I was thrilled to hear from him and acutely aware of the potential for innovation in the remarkable endeavor of industrializing microalgae, leveraging technologies from all over Japan and fostering collaboration across industries. I made the decision that Shiseido should take part as a leading cosmetics company.

Without delay, I informed my boss that the sustainability initiatives would be even more extensive than initially anticipated. From attending the academic conference to participating in MATSURI, it only took a month to realize this.

In preparation for the full-scale operation of the microalgae production facility in Malaysia in April 2023, I proposed to Mr. Okabe, executive vice president and chief marketing and innovation officer, that he visit the facility. He too quickly grasped the significance of the project during his visit. Upon returning to Japan, we presented to other management members, advocating for Shiseido's participation as an Industry Structuring Partner with an investment in MATSURI.

In July 2023, Shiseido made the decision to enter into a strategic partnership agreement focused on research and development. I was struck by the immense enthusiasm that propelled everyone involved forward. We were all motivated to create a prosperous future world in a remarkably short period.

A visit to the micro algae production facility C4, operated as a commissioned project by NEDO*3 (New Energy and Industrial Technology Development Organization), in Malaysia in April 2023. Executive Vice President, Chief Marketing & Innovation Officer, Yoshiaki Okabe (front row center), along with Ito and Oguchi (from the right end of the front row).

―Why did you focus on microalgae among other biomasses?

A notable characteristic of microalgae is its rapid growth. Unlike plants with roots, stems, and leaves, microalgae consist solely of a fruit-like structure found in oilseed plants. This unique composition allows for high production efficiency, with estimated oil yields twice that of oil palm and protein yields sixteen times that of soybeans. The fruit part of microalgae, where growth energy is concentrated, contains abundant proteins, carbohydrates, vitamins, minerals, and fatty acids, making it a valuable source of essential nutrients for humans. Certain types of microalgae also contain unsaturated fatty acids such as EPA and DHA, as well as the antioxidant astaxanthin.

While microalgae are commonly believed to require substantial amounts of water to grow, this is not true; they don’t actually require much. The amount of water needed to harvest one kilogram of protein from microalgae is only around one-fifth compared to equivalent soybean production, minimizing its environmental impact.

Another unique advantage of microalgae is its versatility in terms of land conditions. It thrives with just sunlight and water, making it suitable for production in deserts or salty lands. Microalgae production does not compete with traditional agriculture, making it an environmentally friendly option.

A panoramic view of the microalgae production facility C4 in Kuching, Malaysia. The facility is the largest in the world, covering an area of 5 hectares (approximately the size of the Tokyo Dome). In the background of the photo is an adjacent thermal power plant. From here, carbon dioxide from the exhaust gases is captured and used as a nutrient for microalgae production.

The facility is expected to produce 350 tons of dried microalgae biomass annually while fixing 700 tons of CO₂.

CHITOSE has adopted a facility called a photobioreactor for production. It enables an efficient supply of sunlight and CO₂ with minimal water usage. The facility is neatly arranged on the vast 5-hectare land.

―What does Shiseido do in the MATSURI project?

Currently, our main challenge lies in identifying the oil content in samples and determining the most effective oil processing methods. Additionally, it is essential for us to establish guidelines specifically for the cosmetics industry, as there are currently no existing safety and quality standards for cosmetic materials derived from microalgae.

―How will cosmetics change through the project?

The intensity of the color changes depending on the density of microalgae production. Over approximately three days, the color gradually shifts from the right to the left as seen above. The amount of dried microalgae shown on the right side of the photo represents the growth equivalent to that of a 10-square-meter production facility in Malaysia within a single day.

Microalgae can be processed into solids or liquids for different purposes. The brown liquid in the left bottle is extracted microalgae oil, while the refined version in the transparent bottle on the right serves as a raw material for cosmetics.

―You must have overcome many challenges in raw material development. What is the major difference in this case?

Oguchi: We are embarking on an exciting new venture, marking our first-ever initiative to independently source raw materials, drive cosmetic ingredient development, and introduce innovative alternatives. In this journey, we will collaborate closely with raw material manufacturers, ensuring clear communication of our requirements and unwavering commitment to quality throughout the joint development process.

Identifying promising raw materials is just the beginning. We will actively engage various departments, including production and business units, to spearhead the product development phase. While our esteemed raw material development team has previously taken the lead, this endeavor presents an unprecedented and substantial challenge for us, one that we eagerly embrace.

The four bottles on the left display differences in concentration of the same species of microalgae. The vibrant green color on the far right is due to pigment components, such as chlorophyll. Further research is expected to explore the potential of extracting substances from microalgae.

Igniting the Spark of Innovation: Cultivating a Culture that Embraces Challenges and Celebrates Diversity

―How are colleagues within the company perceiving this project of an unknown field?

When the opportunity to participate in the MATSURI project arose, I anticipated that the team would be thrilled. True to my expectations, they wholeheartedly embraced the challenge of venturing into uncharted territory, their minds brimming with innovative ideas. It's incredible to witness the sheer enthusiasm they exude, as even just walking through the office with dried microalgae biomass ignites a spark of curiosity among our colleagues. Everyone gathers, with eyes gleaming, eager to touch and inhale its scent.

I firmly believe that this project has sparked a multitude of budding ideas throughout the entire organization.

―How do you cope with concerns and risks of failure?

Curiosity is an essential trait for researchers and having unique perspectives and ideas is highly valued. At Shiseido, we have a culture that embraces diversity, so we prioritize listening to and understanding the viewpoints of others.

While Shiseido may be perceived as a company with a conservative and stability-focused mindset due to its 150-year history, personally, I have never felt constrained or limited. It is a company that actively encourages and supports employees in their pursuit of a better future. I strive to be a source of encouragement and support for my team members, just as the company supports and encourages us.

―Finally, please share your thoughts on sustainability.

Personally, I aim to contribute to this vision through the realm of raw materials. It would bring me great joy if those who hold our products in their hands feel a sense of beauty and interconnectedness, not only within themselves but also with the Earth and the future.

Ito: I passionately believe that challenging established concepts can play a significant role in realizing a sustainable society. When we hear the term "environmentally friendly," it is often associated with sacrifice, compromise, or a sense of duty. However, by redefining our limitations and shifting our perspectives, we have the power to bring about a profound societal transformation, introducing fresh and unconventional ideas. We find ourselves amidst this transformative journey, a unique opportunity to forge a harmonious balance that combines both sustainability and luxury.

With unwavering passion and boundless enthusiasm, I am committed to collaborating with individuals from diverse backgrounds, fostering innovation, and working together to create a better world. My goal is to bring about positive change and make a meaningful impact through a collective approach, proudly showcasing the remarkable advancements emerging from all corners of Japan.

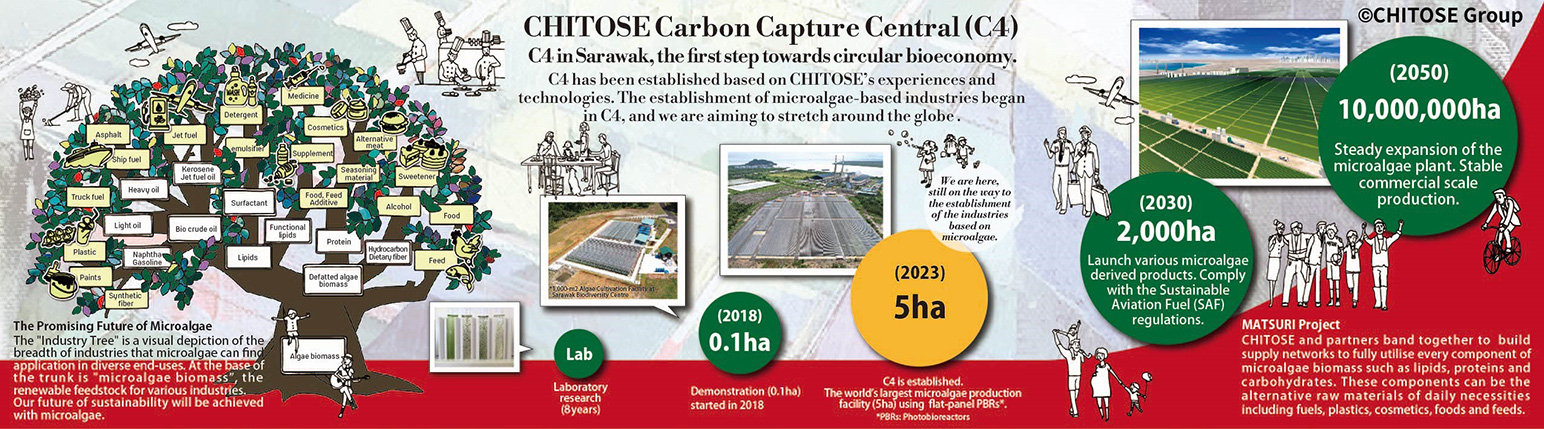

MATSURI Project Plan

There are plans to expand production to 2,000 hectares by 2030. A production system will be established to supply 140,000 tons of dried biomass annually with a production cost of less than 300 yen per kilogram. At this stage, the amount of CO₂ reduction will surpass the CO₂ emissions, leading to a positive impact on the planet.

The goal is to expand production to a scale of 10 million hectares, which is 1/20 of the world's total corn production land by 2050. This expansion aims to achieve a production of 700 million tons of dried biomass with a production cost of less than 60 yen per kilogram (as of 2023/2024, total global corn production is approximately 1.2 billion tons)

- *1:CHITOSE Group, which has strengths in large-scale production and commercialization of microalgae, leads a project to establish a microalgae industry that no one has achieved before, in collaboration with leading companies and government agencies in Japan. As the name "MATSURI" suggests, the project aims to create a sustainable society through the utilization of microalgae and make it a celebration that will go down in human history. The project was selected as an implementation destination for the "Green Innovation Fund Project" by the New Energy and Industrial Technology Development Organization (NEDO) and is scheduled to be carried out in 2023. The production of microalgae in Malaysia is part of NEDO's commissioned project.

- *2:A group of bio-companies leading the global bioeconomy. Through the pursuit of the potential of biotechnology, R&D and business development are being carried out to move us closer to a circular society based on photosynthesis by transforming the current industrial structure of our fields of pharmaceuticals, food, chemicals, agriculture, energy, etc. that is based on fossil resources.

- *3:The New Energy and Industrial Technology Development Organization (NEDO) is a national research and development agency that promotes innovation through the advancement of technology for the realization of a sustainable society. Japan has set a goal to achieve zero greenhouse gas emissions by 2050 and has formulated the "2050 Carbon Neutral and Green Growth Strategy" as its growth strategy, and in support of corporate endeavors, the "Green Innovation Fund" was established within NEDO. This initiative aims to support research, development, demonstration, and implementation, and involves the collaboration of the public and private sectors to share specific goals and provide continuous support to companies and other entities over a period of ten years.

New Energy and Industrial Technology Development Organization (NEDO)

Related links

ABOUT US

-

Who we are

-

History

-

Profile

-

Governance

-

Quality Management

-

Supply Network

-

Region/Business

BRANDS

-

Prestige

-

Premium

-

Inner Beauty

-

Life Quality Makeup

SUSTAINABILITY

-

Strategy / Management

-

Society

-

Environment

-

Governance

-

Reports / Data

-

Related Information

INNOVATION

-

Research and Development

-

Research Areas

-

Research outcomes

-

Product safety

-

Product Development Policy

-

Initiatives for doctors and researchers

CAREERS

-

DISCOVER OUR WORLD OF OPPORTUNITY

- Shiseido careers

INVESTORS

-

IR Library