- Home

- ABOUT US

- Commitment to Quality

- Shiseido Quality Management System

Shiseido Quality Management System

1. Basic Concept

S-QMS is a system that consistently manages and improves quality from product planning to consumer’s use.

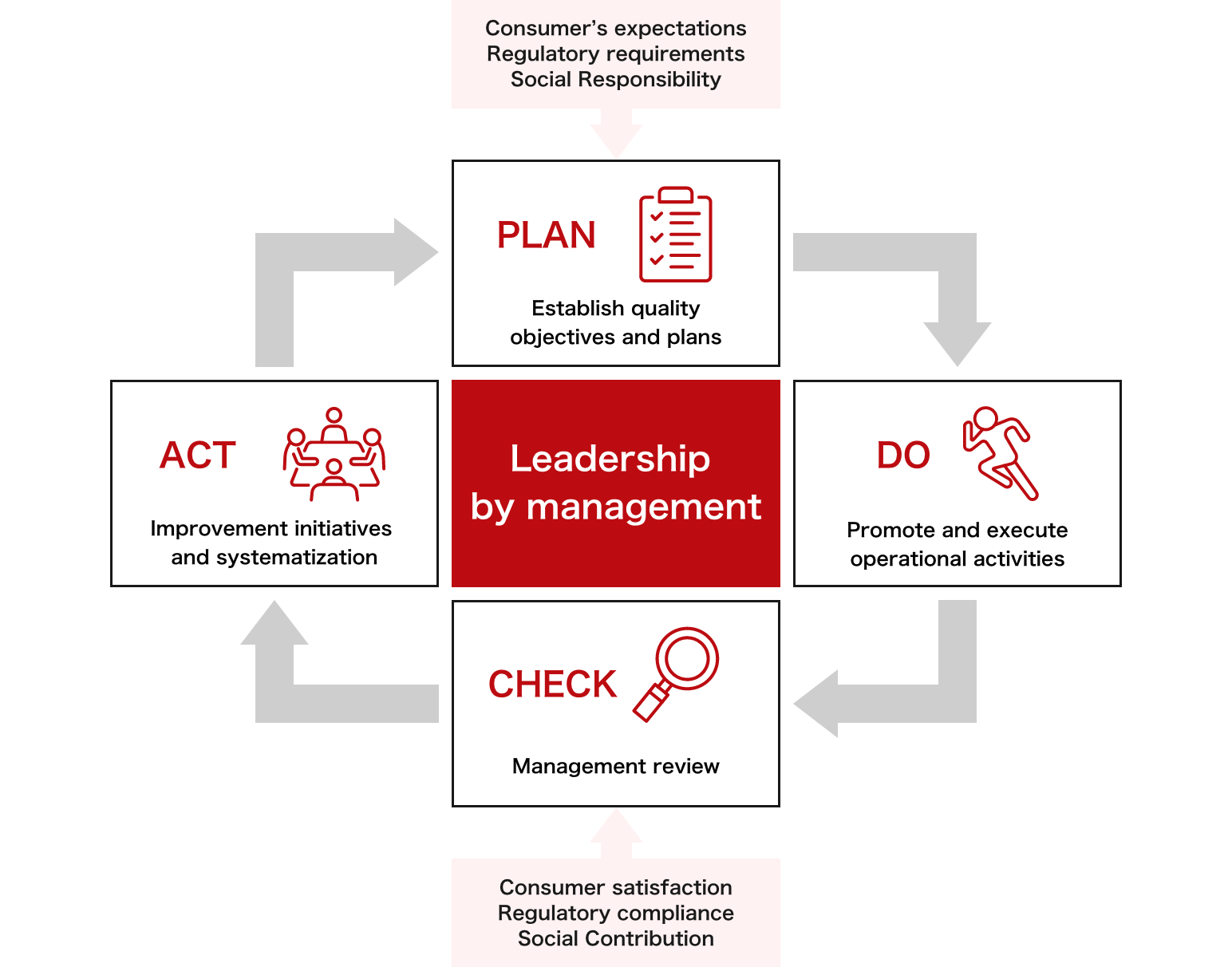

Under S-QMS, we establish our goals in accordance with the Shiseido Quality Principle and involve all employees in quality activities to achieve these targets. Based on the PDCA cycle, we aim to continually improve quality by developing and implementing strategies and action plans.

2. Global Quality Management System

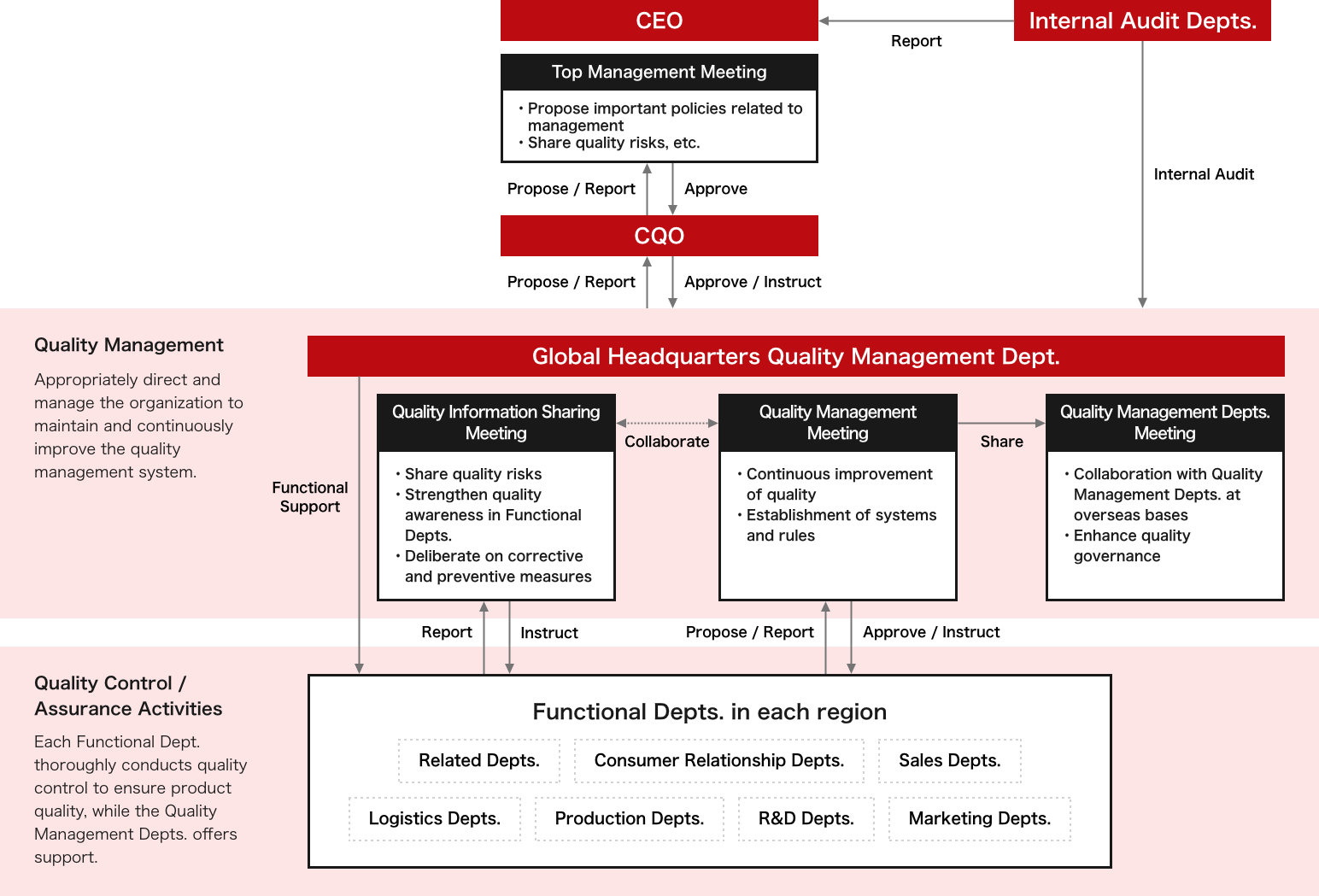

We have established a group-wide quality management system to ensure consistent quality across our global business operations. Each Functional Department thoroughly implements quality control measures to ensure product quality while also holding meetings to share potential risks, discuss corrective and preventive actions, and maintain our systems and rules. Through these meetings, we make proposals and reports related to quality. These meetings are supervised and approved by the Chief Quality Officer (CQO).

Important policies that significantly impact management will be shared and proposed at a Top Management Meeting, as determined by the CQO, leading to decision-making for the entire Group.

Additionally, Quality Management Departments across region collaborate to regularly review and share information about quality activities in each region during these meetings. This process enables global quality management reviews and realizes continuous quality improvement.

3. Governance and Support for Quality Management

Document management, training, and audits are vital system that work together to continuously support Shiseido’s quality management and establish and uphold quality governance throughout the entire Group.

■ Document Management

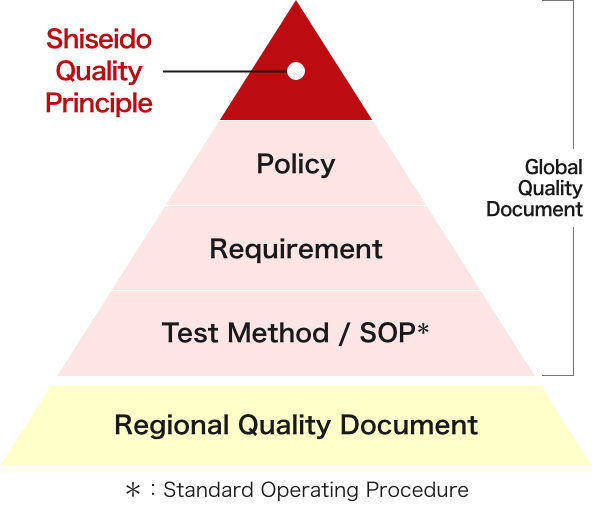

By systematizing rules and procedures for maintaining quality, we facilitate information sharing across the organization and establish a system for operating in alignment with our quality principle. The Global Headquarters establishes and develops common rules for the Shiseido Group, and each base organizes its guidelines in accordance with these rules to ensure compliance with national and regional laws and regulations. We enhance the overall effectiveness of our quality management by maintaining consistent quality worldwide and adapting to regional characteristics.

■ Training

To provide quality that exceeds consumer’s expectations, it is essential that each employee correctly understands the concept of quality and takes action to achieve it. We aim to enhance our understanding and practical skills related to quality through departmental and level-specific training conducted by the Quality Management Departments of the Global Headquarters and each region, as well as through confirmation and evaluation of understanding and retention. We are actively committed to implementing quality education as a core foundation of human resource development, which supports the growth of our employees.

Quality Training at the Factory

■ Audits

Audits are conducted worldwide with the primary objective of confirming compliance with the laws and regulations of each country, as well as with our internal standards.

Through collaboration between the Quality Management Departments of our Global Headquarters and each region, we enhance the accuracy of audits and assess our improvement progress in achieving quality principles and objectives. Through audits that examine various aspects, we aim to maintain and strengthen our quality governance.

ABOUT US

-

Who we are

-

History

-

Profile

-

Governance

-

Quality Management

-

Supply Network

-

Region/Business

BRANDS

-

Prestige

-

Premium

-

Inner Beauty

-

Life Quality Makeup

SUSTAINABILITY

-

Strategy / Management

-

Society

-

Environment

-

Governance

-

Reports / Data

-

Related Information

INNOVATION

-

Research and Development

-

Research Areas

-

Research outcomes

-

Product safety

-

Product Development Policy

-

Initiatives for doctors and researchers

CAREERS

-

DISCOVER OUR WORLD OF OPPORTUNITY

- Shiseido careers

INVESTORS

-

IR Library