Shiseido’s Growth Strategy

Sources of Value CreationSupply Network

Evolution from Supply Chain to Supply Network

As a result of promoting our medium-to-long-term strategy VISION 2020, we achieved our net sales target of ¥1 trillion in 2017, three years ahead of schedule. Amid expanding market demand, strengthening our supply chain has become one of the most important issues for management. Therefore, we took joint efforts with our raw material suppliers and outsourced manufacturing partners to reinforce the supply chain and improve our product supply capabilities in the market. As a result, out-of-stocks, which had been an issue, are gradually declining. Furthermore, we believe that, in the ever-changing market environment, the ability to build an agile supply structure will be of crucial importance going forward. To that end, while precisely capturing the needs of consumers around the world, we will strengthen collaboration with our business partners, build a supply structure that is fast and flexible, and evolve our supply chain into a supply network.

Shiseido's Supply Network

We have four strengths in our supply network.

The first strength is the high level of quality recognized by consumers, resulting from the use of high-quality raw materials carefully selected based on Shiseido’s quality standards as well as from our stringent inspection processes. Currently, overseas sales account for over 60% of our total sales. Meanwhile, the majority of our products are manufactured in Japan, making the most of domestically cultivated production technologies. The fundamental aim of all our initiatives is to further enhance the quality of these products and continue to exceed consumer expectations.

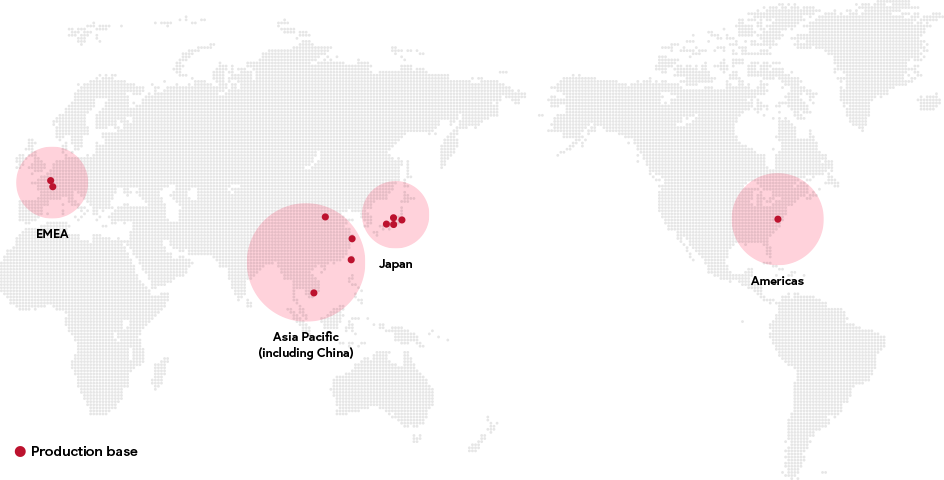

Another strength is sharing the technology and culture of craftsmanship cultivated in Japan with our overseas production bases. Shiseido’s global production network enables it to manufacture products at optimal locations and create business continuity plans (BCPs), which we see as a competitive advantage. Our global manufacturing system ensures production that meets the needs of each region. In addition, we aim to achieve flexible and stable production even in the event of an emergency or a significant fluctuation in demand.

Global Production Network

The third strength is our technological capabilities that contribute to a sustainable society. Since creating our first refillable product in 1926, we have pursued various environmentally focused efforts, including the production of eco-friendly packaging. Based on the technological capabilities we have cultivated to date, we are actively developing technologies to realize innovative products from high-quality raw materials and deliver them to consumers.

Our human resources constitute the final strength. Our supply network personnel have a strong loyalty to Shiseido and take pride in their work at the Company and their ability to create high-quality products. This robust human resource foundation serves as the source of our value creation.

Strengthening Production Capabilities in Japan, Optimizing Inventories, and Eliminating Lost Business Opportunities

In our efforts to improve product supply capabilities, we have been continuously investing in production facilities in Japan. The start of operations at the Nasu Factory at the end of 2019 was the first tangible result of these efforts. Going forward, we plan to gradually commence operations at the Osaka Ibaraki Factory and the Fukuoka Kurume Factory, expanding our domestic production base network to six facilities. While closely monitoring demand levels in each country, we will strive to establish a stable global production network over the medium-to-long term.

Meanwhile, an agile supply structure requires shorter lead times and more accurate demand forecasts. To that end, we will collaborate with our raw material suppliers to shorten these lead times and leverage AI and other technologies to improve the accuracy of our demand forecasts.

By stepping up investments in such areas, we will stabilize our level of supply and, as a result, establish a more agile supply structure. This will allow us to adjust our inventory levels and reduce the number of lost business opportunities due to out-of-stock products.

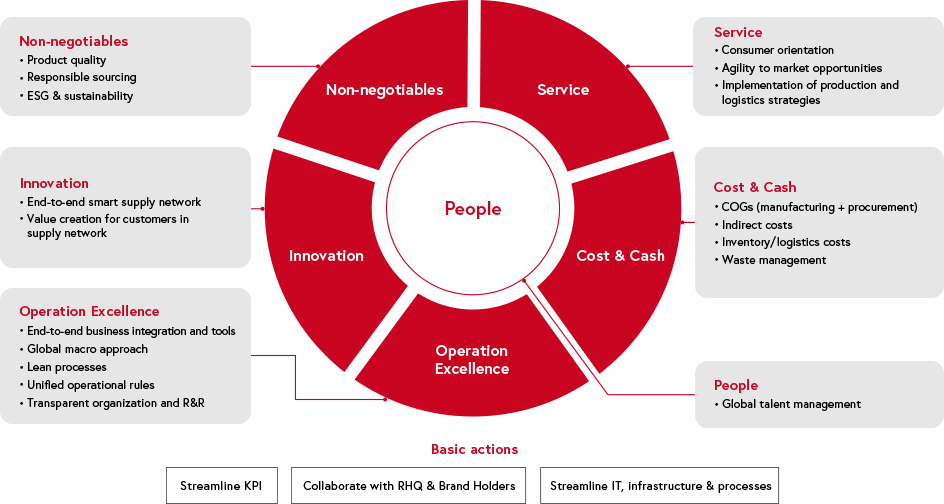

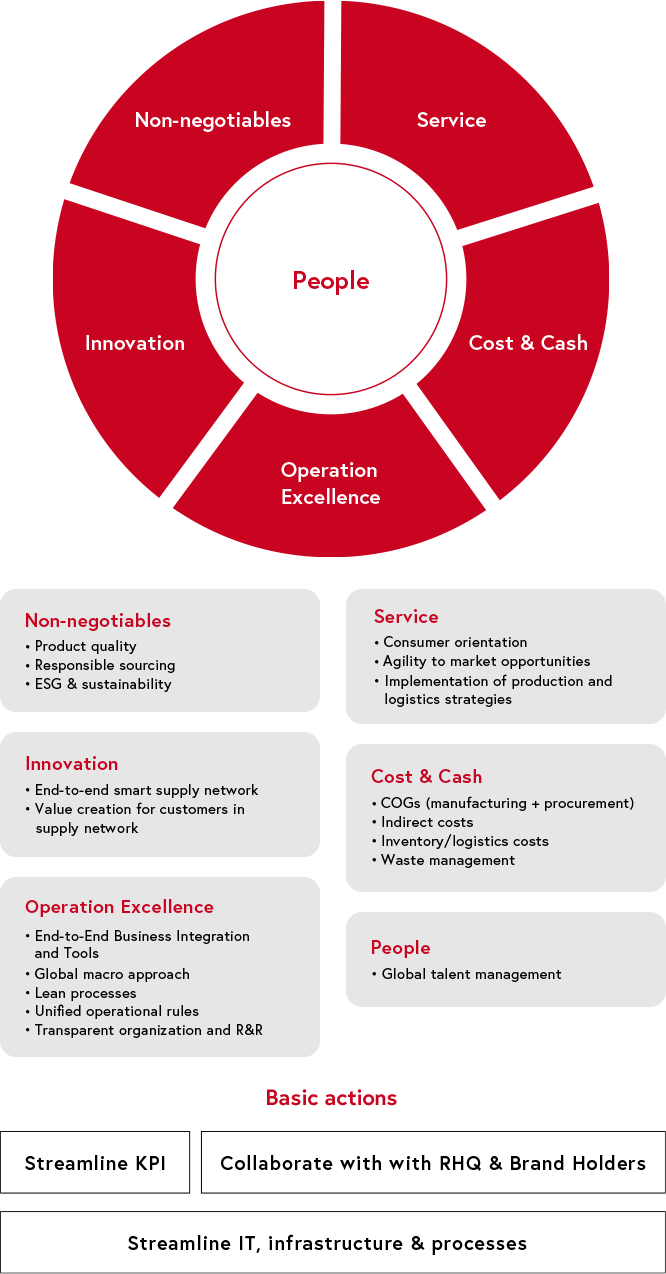

Medium-to-Long-Term Strategies for Our Global Supply Network

We have determined six key initiatives that will form the core of our global supply network’s medium-to-long-term strategies: Non-negotiables, Innovation, Operation Excellence, Service, Cost & Cash, and People. We will steadily advance the evolution of our global supply network by promoting these six key initiatives around the world, formulating measures of the highest priority under these initiatives, and executing them on an annual basis, in accordance with our future vision of the global supply network.

Global Supply Network

Additionally, to realize each key initiative, we will further deepen inter-regional collaboration and enhance cross-boundary communication. As we strive to increase our ratio of overseas sales and accelerate global M&A, we will continue to strengthen cooperation worldwide to generate various synergies.

Amid an uncertain business environment, we will undertake all of these six key initiatives in a flexible and swift manner to support steady growth going forward. In this way, we will aim to realize “BEAUTY INNOVATIONS FOR A BETTER WORLD.”

May 2020

Norio Tadakawa

Director

Executive Corporate Officer

Chief Supply Network Officer