KEY FIGURES

2023 Target for

COGs vs 2019

2pts improvement

2023 Target for

DSI

200days or less

CO₂ emissions at

Osaka Ibaraki Factory

down by

ca.30%

CONTENTS

Q1.What are the characteristics and challenges of Shiseido’s production network?

Q2.What are the key points of the supply network strategy in WIN 2023 and Beyond?

Q3.Please elaborate on the new production sites in Japan, including the Ibaraki Factory in Osaka.

Q4.Please tell us more about the sustainability initiatives in the Shiseido supply network.

Q5.What are your future aspirations as Chief Supply Network Officer?

Q1.What are the characteristics and challenges of Shiseido’s production network?

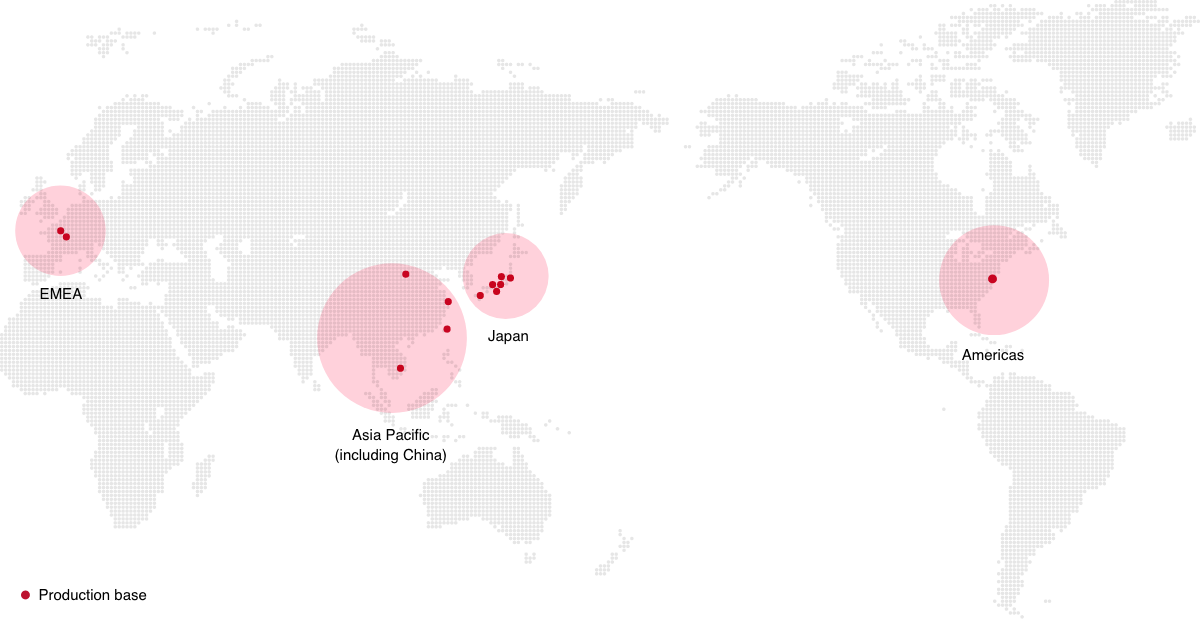

Shiseido supplies products to consumers worldwide from 13 global production bases: seven overseas and six in Japan, including the new Fukuoka Kurume Factory in Kyushu, which is slated to begin operation in May 2022.

At the heart of these factories is the highest standard of uncompromising Shiseido quality, backed by our spirit of monozukuri craftsmanship, a strength greatly valued by our consumers. We follow the same rules, systems, and quality tests at every factory at home and overseas to maintain only the highest standards, ensuring that our factories all use the same technologies and all inherit this monozukuri spirit.

Our global production network also allows us to respond flexibly to the needs of each region. Local production sites mainly manufacture products for brands marketed in that region, ensuring flexible, agile modes of production and distribution. It also contributes to shorter lead times by localizing the procurement of raw and packaging materials, maximized cost efficiency, and better business continuity planning in case of emergency.

However, since around 2017, Shiseido has experienced issues such as tightening supply capabilities resulting from increased demand for our products, which caused significant opportunity losses and inappropriate surplus inventory. While overall production volume decreased from 2020 to 2021 due to the impact of the COVID-19 pandemic, we have been focusing on future growth and working to strengthen our supply capabilities in order to deliver Shiseido products to consumers in a stable and timely manner without missing any growth opportunities.

Another ongoing challenge is maintaining a constant supply of products that respond to consumer needs in a VUCA environment. To this end, we are shifting to real-time operations and improving efficiency using our globally integrated system, FOCUS.

Global Production Map

Q2.What are the key points of the supply network strategy in WIN 2023 and Beyond?

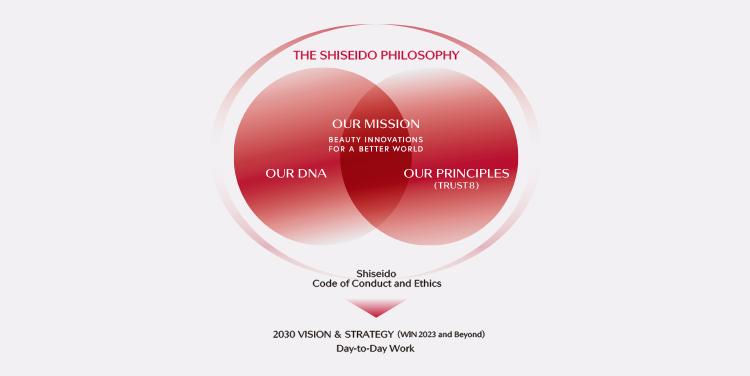

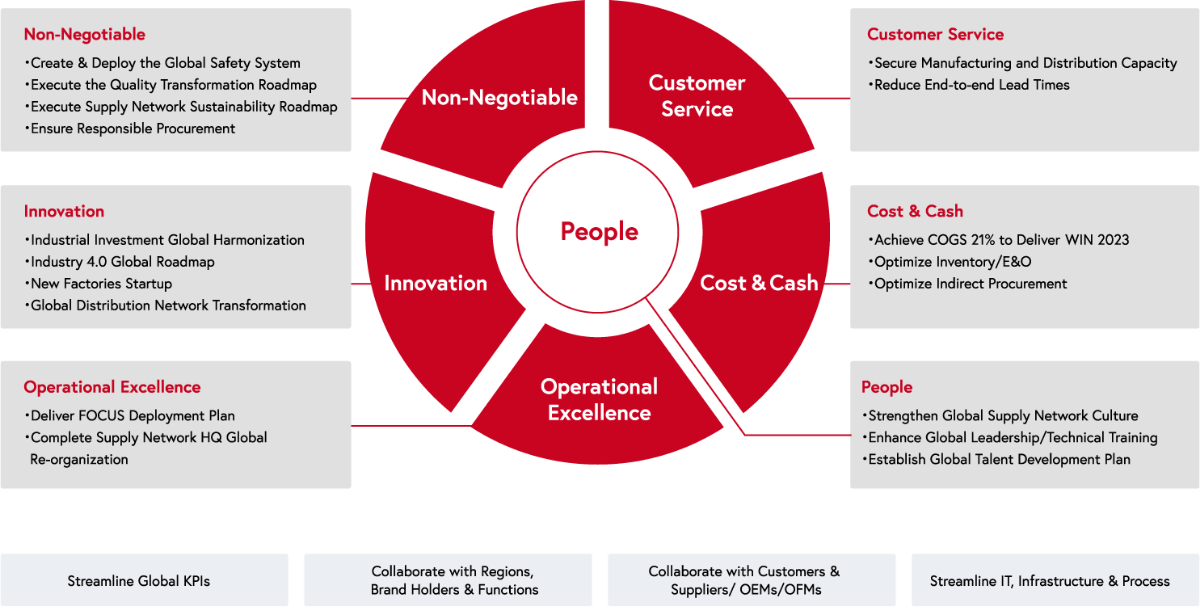

To achieve the targets set out in our medium-to-long-term strategy WIN 2023 and Beyond, we have established six core focus strategies, shown in the figure below, as well as global priority actions for each. We are now working to achieve these goals consistently every year.

Our first focus is on building a system that prioritizes Quality, Safety, and Sustainability as part of our efforts to strengthen the business foundation. Moreover, we are also implementing various organizational changes aligned with our emphasis on the skin beauty category in a bid to strengthen our supply network, improve its cost efficiency, and, as a result, shift to a highly profitable structure.

2022 marks the 150th anniversary of Shiseido’s founding. As such, I see this as a time to build anew, a starting point for efforts to re-examine and modernize our processes across the business to ensure uncompromising Quality and Safety, and create a Sustainable supply network that minimizes our impact on the global environment. In this context, we are building a highly agile and efficient system that ensures stable supply while optimizing procurement, production, and distribution at the global level in line with the restructuring of our brand portfolio and M&A initiatives.

Finally, cost reductions across our supply network will contribute to achieving a Group-wide target operating profit margin of 15% by 2023. Specifically, in addition to improvements to the overall accuracy of demand forecasting through the use of AI and the deployment of IoT and cutting-edge technologies at our factories, we will also optimize procurement prices through collaboration with raw and packaging material suppliers and minimize surplus inventories. We will also introduce FOCUS to synchronize our end-to-end planning and leverage indirect procurement through the standardization and streamlining of systems and processes, and unite all members in our supplier network to achieve our goals as one team.

GLOBAL SUPPLY NETWORK STRATEGIES TOWARDS WIN 2023

Q3.Please elaborate on the new production sites in Japan, including the Ibaraki Factory in Osaka.

Shiseido has launched three new domestic factories since 2019, each with its own role and contribution to our global supply network. The Nasu Factory was the first Japanese production facility built in 36 years, completed and launched swiftly to resolve supply chain issues. The Osaka Ibaraki Factory began operations as a base for production and a state-of-the-art distribution center, with a consumer center located on site, bringing our entire production process closer to the consumer. The Fukuoka Kurume Factory will ensure a reliable supply of premium made-in-Japan skincare products in preparation for future growth, leveraging state-of-the-art digital technologies. All three factories are designed and operating under the highest quality standards, in harmony with their local communities, minimizing our impact on the environment. An integral part of our new factory design is to be open and accessible to local communities and our consumers through a factory tour program, so that our consumers can have direct access to all aspects of the manufacturing process of our products.

The Osaka Ibaraki Factory and the West Japan Distribution Center, which began operations between 2020 and 2021, integrate production, logistics, and distribution functions based on the vision of creating a high-quality manufacturing/distribution facility with an eye on the next century of Shiseido. We have also promoted various initiatives to reform the workplace from the perspective of women, who account for more than 60% of our workforce. One such initiative has introduced a free-address workplace based on an ABW (Activity Based Working) concept, allowing staff members to freely choose how and where they want to work. In addition, we are increasing productivity and reducing workloads by deploying automated delivery of materials and digitization of paperwork.

The adjacent West Japan Distribution Center will take advantage of its location and improve efficiency, shorten lead times, and reduce transportation costs. As Japan’s largest automated warehouse, we have adopted a world-first shipping system called GP3 (Goods to Person for Pick and Pack), a next-generation, multi-shuttle system that automates the reception of goods manufactured at the Osaka Ibaraki Factory, as well as the order preparation for our consumers. GP3 performs everything from picking to packing and labeling simultaneously and contributes to labor savings and best-in-class quality through automation of the end-to-end customer order management process.

Q4.Please tell us more about the sustainability initiatives in the Shiseido supply network.

All our activities are closely tied with sustainability, one of the key pillars in the Shiseido supply network strategy.

We intend on reducing our impact on the global environment to zero. Our supply network teams in each region have collaborated across various communities and joined various initiatives to develop a concrete roadmap for sustainability to achieve this ambitious goal. Our factories and distribution centers worldwide are deploying concrete actions to use renewable energy generated by hydropower and solar power, reduce water consumption, decrease material waste and eliminate landfill waste, procure sustainable raw materials, and re-evaluate containers and packaging.

The Osaka Ibaraki Factory has obtained an A rating under the Comprehensive Assessment System for Built Environment Efficiency (CASBEE), a method for evaluating and rating the environmental performance of buildings and the built environment. The facility has reduced CO₂ emissions by approximately 30% compared to a conventional design through the use of exterior wall materials and equipment, while recirculation and reuse of the cooling water used in manufacturing have reduced 65,000 tons of water consumption per year.

In addition to these environmental conservation efforts to reduce our environmental footprint, it is also essential for us to respect human rights throughout the entire global supply network. In the Shiseido Group Supplier Code of Conduct, Shiseido clearly states the importance of compliance with laws and regulations, anti-corruption, respect for human rights, a safe and healthy working environment, and environmental conservation. We are working hard to ensure an ethical supply network by promoting stringent supplier evaluations.

Another vital issue is providing an environment where employees feel engaged. For our products to make consumers happy, the people who make them must also be happy. A comfortable working space allows us to pay more attention to quality and efficiency. To that end, we focus on creating a diversity-conscious environment and increasing awareness of LGBTQ and other related issues. In addition to the new sites like the Nasu, Ibaraki and Kurume Factories, where these innovations are already in place, we are committed to continued investment in our employees and better working environments at existing factories, distribution centers, and offices.

Q5.What are your future aspirations as Chief Supply Network Officer?

When I was appointed Chief Supply Network Officer in January 2021 after 30 years of experience in end-to-end operations at other global beauty companies, I was impressed with Shiseido’s DNA and a corporate culture built over its long history.

My role is to marry this unique Shiseido culture with modern, innovative and responsible supply network strategies to realize our corporate mission, BEAUTY INNOVATIONS FOR A BETTER WORLD, and medium-to-long-term strategy WIN 2023 and Beyond. I will continue to take on the challenge of leading the transformation of our supply network into one that is highly efficient, agile, responsible, and inclusive, while always being in step with the global environment and global consumer expectations.

I also hope to build a great team by accelerating diversity and inclusion, encouraging members to grow, empowering them to thrive in their work and creating a culture of active engagement and innovation. After all, the value of a company is only as great as the people behind it.

April 2022