Sustainable Packaging

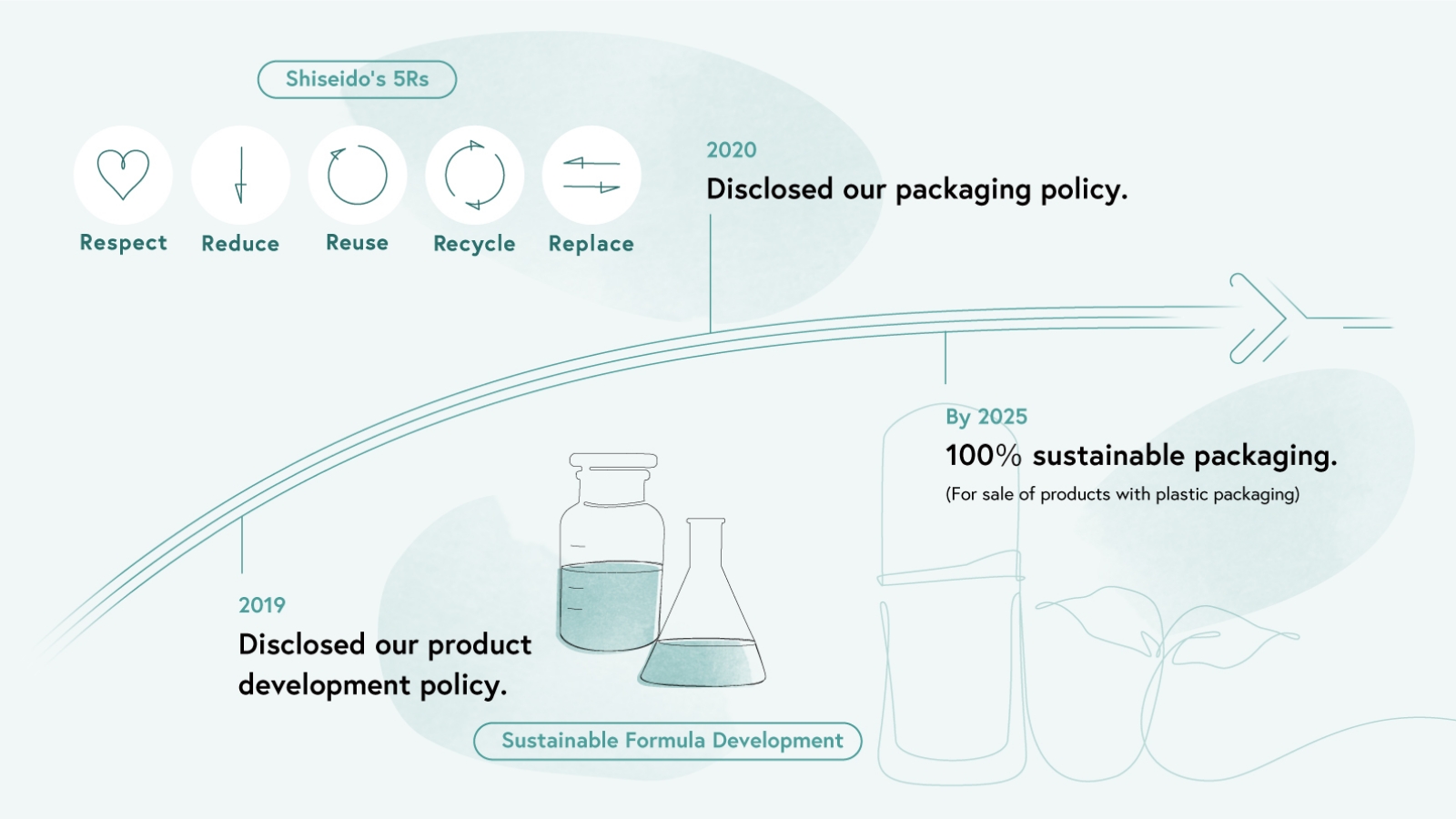

The world needs urgent solutions to mitigate climate change and reduce marine plastic pollution. Stakeholders, including consumers, awareness of climate and environmental issues is expected to increase more than ever. Responding to these changes in consumer awareness is critical to the sustainability of our business. At Shiseido, we strive to cut our environmental impact and create a circular economy through our own packaging development policy: Shiseido’s 5Rs : respect, reduce, reuse, recycle, and replace.

To achieve our goal of 100% sustainable packaging by 2025, we promote recyclable and reusable designs, as well as the use of biomass-derived and post-consumer recycled (PCR) materials. We are specifically working to reduce packaging weight, develop refillable packaging, and design packaging that is easy to recycle .In addition, we are building a Shiseido circular business model that recycles used packaging as new resources in collaboration with consumers and external partners.

Reduce and Reuse

In line with Shiseido’s 5Rs packaging development policy, we are reducing the amount of plastic we use by optimizing the size of packaging to suit the product, reducing packaging weight, and offering refillable packaging.

Our Life Cycle Assessment shows that refillable packaging significantly lowers resource use, waste, and CO₂ emissions compared to continuously disposing of regular (primary) packaging. In order to make a significant contribution to reducing the burden on the environment, we aim to promote the development of these products widely, not only in Japan but also on a global scale.

Since we launched our first refillable product in 1926, we have provided refillable packaging in a wide range of product categories, including skincare and makeup. In 2022, we offered refillable packaging for more than 770 stock keeping units (SKUs) within 30 brands globally. This included increasing refillable packaging under our prestige brand Clé de Peau Beauté and releasing a refillable cream, La Crème. Compared to regular (primary) packaging, the refillable version of La Crème uses 95% less plastic. In 2022, sales of refillable packaging from Clé de Peau Beauté increased 30% year on year.

We are also incorporating innovative technologies to reduce environmental impact. Through SHISEIDO, in 2023 we became the first company to sell cosmetics in packaging made with LiquiForm® technology. LiquiForm® brings together the “bottle-molding” and “filling” process into a single step. Refillable cosmetics packaging made with LiquiForm® can reduce plastic usage per packaging by approximately 70%. Moreover, compared to our conventional refillable packaging (of the same volume), this technology can reduce CO₂ emissions across the entire supply chain―from raw material procurement and production to use and disposal―by around 70%.

In 2022, Shiseido China collaborated with China’s Ministry of Ecology and Environment (MEE) and the Alibaba Group to publish China's first white paper on refillable beauty products. Shiseido China will collaborate with MEE and Alibaba to promote the use of refillable beauty products and advocate for greener consumer behavior respectively.

Recycle

To realize a circular economy, it is important to select materials and design products with the reuse of resources in mind. To reduce our consumption of single-use plastic, we are developing packaging made from a material that can be more easily sorted and reused/recycled after use, without compromising the quality of the packaging’s design.

In 2022, a number of our brands launched products with packaging that is easier to recycle, including SHISEIDO and Clé de Peau Beauté. In addition, the tube packaging for SIDEKICK―a cosmetics brand launched for young male consumers in 2022―is made of easily recyclable aluminum.

Replace

To mitigate climate change and marine plastic pollution, we are focusing on the research of post-consumer recycled (PCR) materials, plastic alternatives, and biomass-derived materials with low environmental impact―and promoting their use.

From 2022, for example, we transitioned Ultimune™, SHISEIDO’s iconic serum, to refillable packaging made from 100% recycled glass. Additionally, Ultimune™ switched its acrylic in-store visual merchandising elements to 100% recycled materials―significantly reducing its use of virgin plastic. We also use some biomass-derived materials in the products and packaging of various other brands, including our ANESSA suncare brand and BAUM skin & mind brand.

We are working with other companies in the industry to start replacing the plastic Point of Sale Materials (POSM) placed in drug stores in Japan with paper POSM. In 2022, we switched approximately 70% of our plastic POSM in Japan to paper.

Initiatives to Build a Circular Model

Shiseido started a new scheme to collect used plastic cosmetics packaging in stores, utilizing a wide range of business partners and consumer touchpoints. As well as increasing consumer awareness about the value of used containers as a recyclable resource, we hope the scheme will help drive wider behavioral change in society and encourage competitors and companies in other industries to implement circular models.

In-store Collection and Recycling

To support and promote recycling, we collect used cosmetics packaging in-store and recycle it as new materials. We work with multiple parties to ensure containers are recycled fully and correctly, including customers, waste collection companies, and other companies.

Our skincare brand IPSA, for example, operates a recycling program at a country and area to reduce its environmental impact and promote environmental awareness among consumers. In 2022, the brand collected approximately 63,000 (1,400 kg) cosmetics containers in China through 94 stores, and approximately 22,000 containers in Taiwan.

In Japan, we collected around 30,000 used containers through 88 AEON stores in collaboration with Aeon Retail Co., Ltd., TerraCycle Japan, and other companies.

Collaborating to Build a Circular Economy for Plastic Cosmetics Containers

When developing cosmetic containers, much importance is placed on protecting the contents, ensuring ease of use, and giving the container a great look and feel. As a result, they have to be made from a wide variety of materials, which can make it challenging to recycle them back into reusable plastic resources.

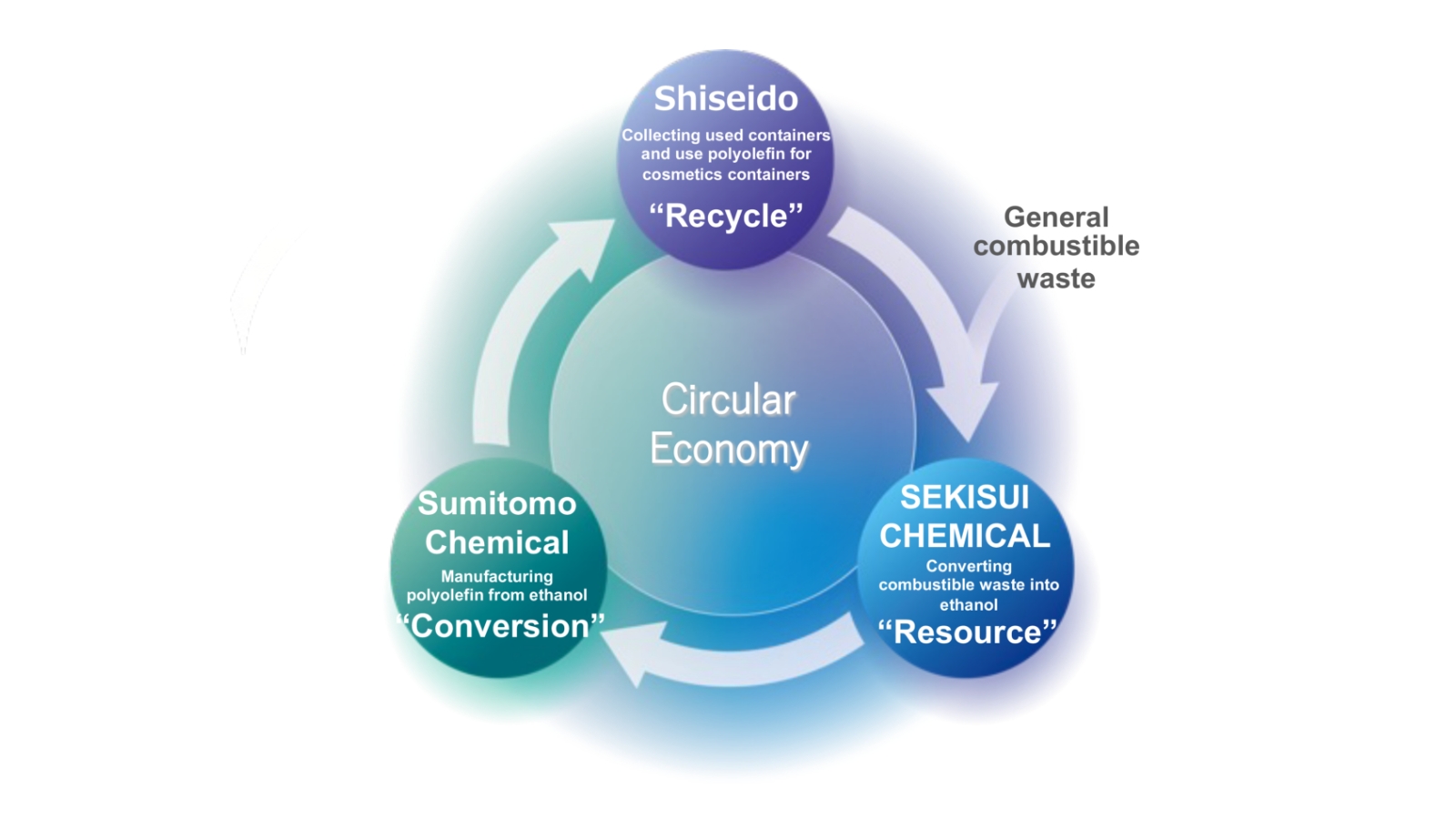

To solve this issue, Shiseido launched an initiative in 2022 in collaboration with SEKISUI CHEMICAL CO., LTD. and Sumitomo Chemical Co., Ltd. The initiative involves creating a circular economy in which plastic cosmetics containers are collected and recycled without separating the materials. The three companies will be advancing this cross-sectoral alliance, while also calling on related industries and companies to join the effort to create a circular economy.

“BeauRing” Circular Model Project for Plastic Cosmetics Containers

In 2023, we launched the “BeauRing” project―a circular model project to collect and recycle plastic containers into new ones for reuse. As well as driving in-house initiatives, we are encouraging other companies to join the project to expand the circle of resource circulation and, ultimately, create a sustainable society in which consumers use cosmetics with a more positive mindset. In April 2023, we began collecting used containers from several Shiseido product retailers in Yokohama. The POLA brand of POLA ORBIS HOLDINGS INC. joined in the project.

Participation in Related Initiatives

R Plus Japan Ltd.

To play a part in solving the global plastics recycling challenge, Shiseido invested in R Plus Japan in 2022 and engaged in recycling used plastics. By bringing together companies across the plastic packaging industry―from monomer and polymer manufacturers to packaging producers, trading, food and beverage companies―R Plus Japan aims to commercialize an efficient, low-environmental impact recycling technology by 2030.

Formulas/Ingredients

Shiseido develops and provides safe and high-quality products and services based on more than a century’s experience in dermatology and material science.

From an environmental perspective, the sustainable and responsible procurement and use of these products is of the utmost importance. Our Global Innovation Center in Yokohama, Japan, which manages all regional centers, is working to select raw materials and develop formulations that are not only safe and functional but also respect the environment. In line with green chemistry principles, we carefully evaluate our raw materials, ingredients and formulas to ensure they are safe for the human body, have minimal environmental impact, and use natural and upcycled materials sourced through ethical procurement.

Environmental Initiatives

UV Care

We are accelerating innovation in the field of suncare to protect against UV and pursue coexistence between people, their ecosystems, and the environment. The effect caused by the climate change, UV exposure for people around the world is expected to increase. Exposure to UV rays over extended periods of time causes spots and wrinkles on the skin–symptoms of photoaging.

We have developed an innovative new technology to convert UV light into visible light (skin-beautifying light) that has beneficial effects for the skin. We will continue our research in order to provide products and services with added benefits, including innovations like this that help people coexist more harmoniously with the environment.

We are assessing the impact that UV filters used in suncare products have on the ocean. This includes working with the University of the Ryukyus to assess the impact of each UV filter used in our products on coral, and performing simulations of how suncare products spread into the ocean when used by people at the seahore. We are utilizing the results of these assessments for ingredient selection and the development of coral-respecting formulas, while applying them to suncare product development for both SHISEIDO and ANESSA.

In 2023, in order to evaluate the impact of cosmetic ingredients on marine ecosystems, we began a partnership agreement with Innoqua Inc., a start-up company with proprietary technology that reproduces ecosystems in an aquarium. The aquarium can reproduce possible future environmental change scenarios, including ‘rising seawater temperatures’, which are predicted to have a tremendous impact on marine life. This allows us to evaluate the impact of various cosmetic ingredients, such as those used in sunscreen, on the entire marine environment, including coral and other organisms.

Transparent Information Disclosure

Disclosing Our Products Policy

At Shiseido, we want to help tackle issues concerning people’s health and the environment. Therefore, we disclosed our company policies regarding the use of ingredients and raw materials that could be concerning for consumers, such as oxybenzone and parabens.

We comply with all relevant regulations in each country where we operate. In addition, we have our own in-house standards for ingredients–and only select ingredients that meet our strict safety, environmental, and ethical standards.

Procuring Sustainable Raw Materials

Shiseido strives to procure environmentally friendly, sustainable raw materials.

Palm oil is used in cosmetics and household goods for a range of purposes, including as a humectant and as an oil. However, palm oil production can have a significant impact on the environment. We have disclosed our medium- to long-term targets for the procurement of sustainable palm oil, as well as our goal to switch from palm oil to more sustainable raw materials.

Brands That Cater to Consumer Needs

When selecting a product, consumers increasingly place importance on a company’s approach to social responsibility, environmental protection, and ethical raw material sourcing. At Shiseido, in addition to disclosing our corporate policy on ingredient and raw material sourcing, we work to develop brands with a strong environmental, social and ethical profile.

Drunk Elephant originating in the US, for example, is a leading brand in the clean beauty market sold in 40 countries and regions, known for its sustainable and responsible raw material procurement as well as its promotion of sustainable action. Taking this stance, the brand has gained significant support from Millennial and Generation Z consumers.

BAUM was established around the theme of coexistence with trees and offers environmentally friendly products. Its containers, for example, use sustainable raw materials―such as upcycled wood from furniture scraps, plant-derived PET, and recycled glass―and many containers are refillable. The brand is also growing its own forest by planting oak trees in the BAUM Oak Forest in Iwate Prefecture, Japan―some of this wood is even used as a raw material for packaging. Prior to being planted in the forest, the saplings are nurtured in BAUM stores.

In 2022, we launched the Ulé skincare brand in France. Based on plant-derived ingredients, Ulé promotes beauty both inside and outside the body. The brand emphasizes responsible procurement, product efficacy and safety, lower environmental impact, and transparency. To ensure clearer raw material traceability and reduce environmental impact from transportation, the brand buys its three botanical treasures (centella, coleus and tulsi) and produces all its products locally in France. The names and origins of the raw materials can be found on the brand website.

Ulé was awarded the Young and Sustainable Brand Prize in the "Prix d'Excellence Marie-Claire" 2023, the most prestigious beauty awards in France.

No Animal Testing

We strive to provide safe and effective products to consumers while complying with cosmetics regulations and respecting the principles of animal protection. For all our cosmetics and quasi drugs, we have established a safety assurance system based on alternative methods using cell cultures or in silico, etc., that do not involve animal testing. We continue to develop effective alternatives to test product safety, and work with administrative agencies in various countries/regions to certify these methods as official, according to the laws and regulations of the given countries/regions.

In February 2023, we announced our involvement in the newly launched International Collaboration on Cosmetics Safety (ICCS). A global project involving more than 35 cosmetics manufacturers, suppliers, industry associations, and animal protection organizations, ICCS’s goal is to promote and implement animal-free safety assurance in the development of cosmetics and personal care products.

Initiatives with External Institutions

Granting Technology License to Toyo University for Environmental Impact Reduction

In March 2020, Shiseido became the first WIPO GREEN partner company from the cosmetics industry. In 2022, we granted Toyo University a license to use our low-energy manufacturing technology, which is listed in the WIPO GREEN database. Through joint research, Toyo University developed a low-environmental impact, sustainable hand serum using extract from boysenberries harvested near the university.

Developing Cosmetic Ingredient Using Protein Fiber and Formulate It into Products

In 2022, we jointly developed a cosmetics ingredient using Brewed Protein™ , a biodegradable fiber made of plant-derived biomass developed by Spiber. This environmentally friendly material is being used in Shiseido mascara products to create supple and beautiful eyelashes. We are now looking into further applications of the fiber in other Shiseido products.

Exploring the Possibilities of Algae in the MATSURI Project

Shiseido has joined the MATSURI project, the world’s first corporate joint project to explore how algae can be used to drive a sustainable future. Powered by the sun, algae absorb CO₂ through photosynthesis, while also generating useful proteins, lipids, and carbohydrates. More extensive use of algae is expected to contribute to lower CO₂ emissions in future, where algae products can replace fossil-derived raw materials. MATSURI Project partner companies will work together to develop new business opportunities for the cosmetics industry using algae as a raw material.